Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

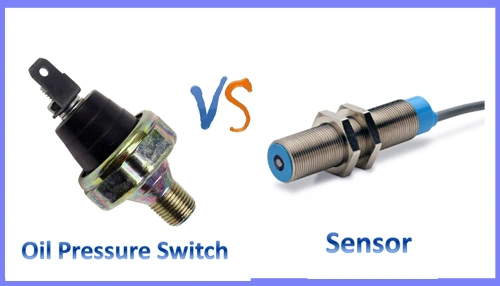

The monitoring of engine oil pressure is a critical aspect of maintaining the health and performance of an automobile’s engine. To accomplish this, two essential components come into play: the engine oil pressure switch and the engine oil pressure sensor.

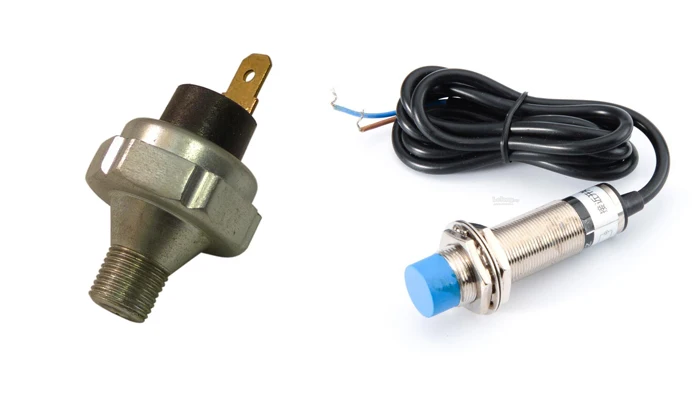

Switches are often brass or steel, while sensors are typically made of ceramic or semiconductor materials. When the oil pressure drops below a certain level, the switch will activate an alarm or turn on a warning light. In contrast, the sensor measures the oil pressure and sends data to the vehicle’s engine control unit (ECU).

Here, I will discuss the intricate details of the oil pressure switch vs sensor. I will present the technical information about their functions, compatibility, and vehicle operation.

The differences between an engine oil pressure switch and a sensor in a vehicle can be categorized into several points. As far as I can tell from my research, the main differences are:

When differentiating between the engine oil pressure switch and sensor in a vehicle, I believe one important distinction lies in the materials used.

Oil pressure switches are typically constructed with mechanical components and simple electrical contacts.

Conversely, oil pressure sensors are electronic components usually made from materials like brass or stainless steel. These materials are chosen for their durability and ability to withstand the harsh conditions inside an engine.

The engine oil pressure switch serves as a basic on/off device that monitors oil pressure. Basically, the system provides a simple indication of low oil pressure by activating and sending a signal to the oil pressure gauge on the dashboard.

On the other hand, the engine oil pressure sensor is an electronic component that continuously measures oil pressure and communicates with the automobile’s engine control unit (ECU). Providing real-time oil pressure data allows the ECU to adjust the fuel mixture or ignition timing for optimal engine protection.

To understand the differences in data output between the engine oil pressure switch and sensor in a vehicle, consider how each component communicates.

The oil pressure switch provides a binary output, indicating whether the oil pressure is low or sufficient. This information is primarily for the driver’s awareness.

Alternatively, the oil pressure sensor offers a continuous numerical value representing the oil pressure range. This precise data is crucial for engine management, monitoring, and diagnosis. Using this device, the computer system of the vehicle can monitor and adjust oil pressure fluctuations at the moment.

According to my research, in most engines, the oil pressure switch is located near the oil pump, near the engine block. Its location allows for easy access during maintenance or replacement.

On the other hand, the oil pressure sensor is also usually situated near the oil pump, but its placement is strategic for optimal engine performance and protection. It’s oriented towards interacting with the vehicle’s electronic control unit (ECU), which requires real-time data for adjustments.

Therefore, the oil pressure sensor is strategically positioned to ensure accurate readings and efficient communication with the ECU.

The compatibility of your vehicle with an oil pressure switch or sensor depends on its make, model, and engine specifications. I suggest consulting the vehicle’s manual or contacting the manufacturer to determine the type of oil pressure monitoring system you need.

Older vehicles, especially those with simpler engine control systems, may only have an oil pressure switch installed. These switches are typically binary, meaning they turn on or off depending on the oil pressure level.

Conversely, newer vehicles with advanced engine control and monitoring requirements will likely be equipped with oil pressure sensors. These sensors provide more accurate and detailed information about the engine’s oil pressure, making it easier to monitor and control the vehicle’s performance.

Unlike the oil pressure switch, which is primarily focused on activating the warning light, the oil pressure sensor plays a dual role. It not only provides real-time data to the vehicle’s Engine Control Unit (ECU) but also triggers the warning light when necessary.

The oil pressure sensor continuously monitors the oil pressure and sends the information to the ECU, determining whether the pressure is within the acceptable range. If the pressure drops below the specified threshold, the ECU instructs the warning light to illuminate, alerting you to the low oil pressure condition.

The engine oil pressure switch is primarily responsible for indicating low oil pressure to the driver through a warning light. It doesn’t have a direct influence on the vehicle’s operation or engine control.

In contrast, the oil pressure sensor actively communicates with the Engine Control Unit (ECU) and plays a crucial role in maintaining engine health. The sensor can provide real-time data on oil pressure to the ECU, which can then adjust the fuel mixture or ignition timing to protect the engine.

In some cases, I found that the sensor could automatically shut down a system to prevent further damage from occurring. Therefore, while the oil pressure switch warns, the oil pressure sensor actively contributes to the vehicle’s operation by protecting the engine.

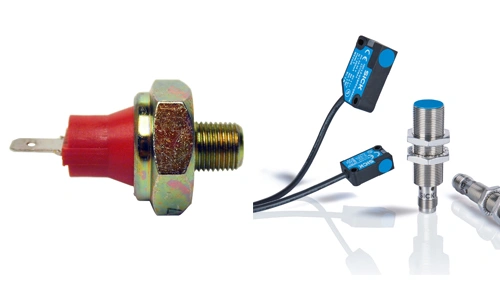

Oil pressure switches are relatively easy to access and replace, making maintenance straightforward. It’s a simple on/off switch that’s relatively easy to access and replace.

Meanwhile, oil pressure sensors are likely to require more complex procedures for maintenance or replacement due to their integration into the engine management system.

Regarding cost, the engine oil pressure switch is the more economical option. Due to its simpler design and fewer components, it is less expensive to manufacture and more affordable to consumers.

On the other hand, the oil pressure sensor, with its advanced electronic components and real-time monitoring capabilities, tends to be more expensive. The additional technology and features in the sensor increase its production costs, which are ultimately passed on to the customer.

Based on my research, if the oil pressure switch isn’t functioning correctly, it can cause harm to your engine. When the switch malfunctions, it can give false readings, indicating that the oil pressure is low when, in reality, it’s at a normal level. This can cause unnecessary worry for the driver.

Moreover, if the switch fails to detect low oil pressure, it may not activate the warning light or alert the driver, putting the engine at serious risk of damage. Hence, it’s crucial to regularly check the oil levels in your car and take immediate action if any issues with the oil pressure switch arise.

If your oil pressure switch is broken, you shouldn’t continue driving your vehicle, as it can lead to potential engine damage. Without proper oil pressure, the engine’s moving parts may not receive the necessary lubrication, leading to increased friction, overheating, and potential engine failure.

To determine if your oil pressure sensor is faulty, I recommend checking for any warning lights on your dashboard indicating low oil pressure. If the oil pressure warning light is illuminated, it could indicate your oil pressure sensor is bad. Furthermore, your oil pressure gauge may read incorrectly or fluctuate abnormally.

Based on my research, I believe that a defective oil pressure switch could potentially cause oil leakage in a vehicle’s engine. On the dashboard, the oil pressure gauge receives information from the oil flow pressure switch about the oil pressure within the engine.

When the switch is not functioning properly, the oil pressure gauge may become inaccurate or fail entirely, leading to a lack of awareness regarding low oil pressure levels. This lack of awareness can ultimately harm the engine components, leading to heightened wear and tear and eventually resulting in oil leakage.

I found the 3 reasons why an oil pressure sensor may fail. One common cause is an internal short in the sensor, which can result in a constant high reading or a complete signal loss.

Another possible cause is damage to the wiring harness, which can disrupt the transmission of the sensor’s signal. Corrosion or a loose connection in the plug can also lead to sensor failure.

Additionally, if the sensor isn’t properly installed or is subjected to excessive vibrations, it can become damaged and fail to provide accurate readings.

Differentiating an engine oil pressure switch and a sensor are crucial to understanding their roles in a vehicle’s functioning. They may seem similar on the surface, but their divergent functionality, data output, and influence on vehicle operation make them crucial to an automobile’s durability and reliability.

If the oil pressure switch isn’t working, it can lead to severe engine damage. Driving with a broken oil pressure switch isn’t advisable as it can result in catastrophic engine failure. A bad oil pressure switch doesn’t directly cause leaks but can contribute to other issues.

Similarly, various factors can cause an oil pressure sensor to fail, including wear and tear and electrical malfunctions. So, I believe it’s important to identify signs of a faulty oil pressure sensor to prevent potential engine problems.

Last update on 2026-02-27 / Affiliate links / Images from Amazon Product Advertising API