Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

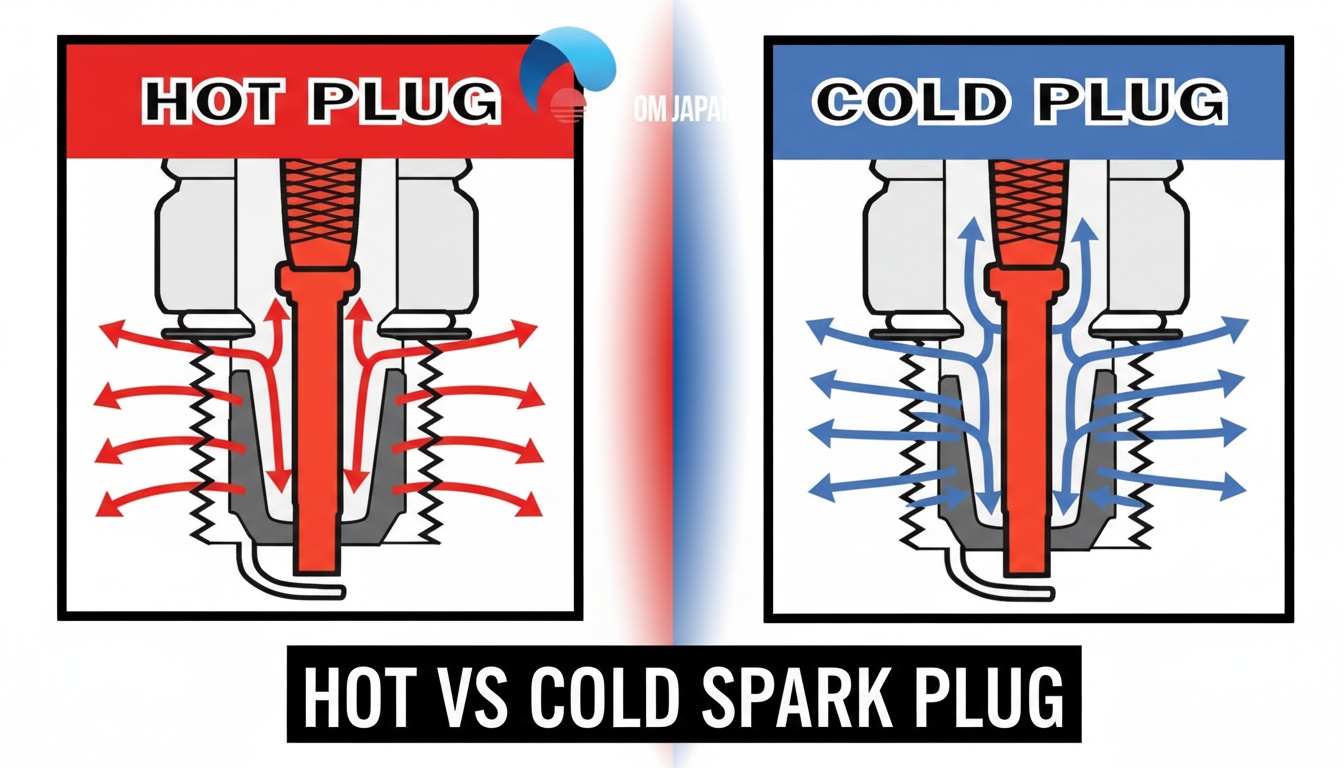

You’ll want hot spark plugs for cooler engines or low-power setups because their longer insulator noses retain heat. This prevents fouling by sustaining self-cleaning temperatures around 500°C+.

Cold plugs, with shorter, thicker insulator noses, rapidly dissipate heat to handle high-performance or forced-induction engines prone to overheating. Using the wrong type risks misfires, pre-ignition, or carbon buildup.

Understanding heat range, design nuances, and operating conditions helps optimize performance and engine longevity. Explore these factors for precise plug selection.

| Feature | Hot Spark Plug | Cold Spark Plug |

|---|---|---|

| Heat Retention | Retains more heat at the firing tip | Dissipates heat quickly |

| Insulator Nose | Longer, thinner insulator nose | Shorter, thicker insulator nose |

| Ideal Engine Type | Low-power or cooler-running engines | High-performance or high-RPM engines |

| Fouling Resistance | Excellent at preventing fouling | More prone to fouling in low-load use |

| Overheating Risk | Higher risk in high-output engines | Lower risk of pre-ignition |

| Best Use Conditions | Cold climates, frequent idling | Hot climates, racing, heavy loads |

| Common Risks | Pre-ignition, overheating | Carbon buildup, misfires |

When you compare hot and cold spark plugs, you’ll notice they differ primarily in how they manage heat within the combustion chamber.

Hot and cold spark plugs mainly differ in their approach to managing combustion chamber heat.

Hot spark plugs run hotter because their ceramic insulator has a smaller contact area with the metal body. The longer, thinner insulator nose retains heat, limiting heat dissipation. This design suits low-power engines or standard heat environments, allowing the plug tip to reach peak temperatures quickly.

As a result, a hot plug can burn off deposits more effectively due to the higher operating temperature. This thermal management is crucial for maintaining ignition stability and preventing fouling in such engines.

In contrast, cold spark plugs dissipate heat more rapidly due to a larger ceramic-to-metal contact area. They’ve a short, thick insulator nose that transfers heat efficiently to the metal shell. Their shorter electrode tip and enhanced heat transfer prevent overheating, making them ideal for high-performance engines exposed to intense combustion temperatures.

Proper heat range selection, as emphasized in advanced spark plug designs, ensures optimized performance and longevity under such conditions. These fundamental design differences directly affect thermal management and engine performance.

Although several factors influence it, the heat range of a spark plug primarily depends on how effectively its ceramic insulator nose dissipates heat.

The insulator’s length and surface area dictate the heat transfer rate: a longer nose slows heat dissipation, keeping the firing end hotter, while a shorter nose facilitates rapid heat transfer to the cylinder head.

Thermal conductivity of the insulator and center electrode materials also plays a critical role. Proper maintenance and monitoring of engine components, including valve train elements, can impact overall combustion conditions affecting spark plug performance.

Optimal firing end temperatures range from 500°C to 800°C; below 500°C, fouling risks increase, and above 950°C, pre-ignition becomes likely. The spark plug also functions as a heat exchanger by transferring heat from the combustion chamber to the cylinder head and cooling system, which helps maintain these optimal temperatures heat exchanger function.

Manufacturers assign numerical heat range values; lower numbers indicate hotter plugs, reflecting thermal performance, not electrical characteristics.

Engine conditions such as forced induction, mixture richness, and ignition timing further influence the ideal heat range selection. Additionally, issues like camshaft or lifter wear can cause misfires or rough running, indirectly affecting spark plug behavior and heat management engine performance factors.

Did you know that hot spark plugs have a longer insulator nose? This clever design helps retain heat at the firing end because it extends the heat flow path to the metal shell.

So, what does that mean for your engine? Well, it slows down thermal dissipation, which keeps those temperatures nice and high within the combustion chamber. This means hot plugs transfer heat more slowly and are typically used to avoid fouling in cooler chambers, making them ideal for certain engine conditions heat transfer.

Choosing the right plug also depends on factors like engine temperature and riding habits to prevent contamination and maintain efficiency oil change intervals. Understanding how these features control heat retention and transfer is really important. It can help you optimize spark plug performance for specific engine conditions.

Since the insulator nose length directly affects heat retention, you should understand that hot spark plugs feature longer noses to increase the distance heat must travel before dissipating to the cylinder head.

This extended conduction path forces combustion heat to travel farther, maintaining ideal firing tip temperatures between 500°C and 800°C. You’ll notice that the longer, thin nose design in hot plugs not only heats rapidly but dissipates heat slowly, exposing more surface area to ignited gases.

In contrast, cold plugs have shorter, thicker noses, which shorten the heat path for faster cooling. Manufacturers use nose length as a key parameter in heat range classification. Longer noses correspond to lower heat range numbers, such as NGK’s scale.

Selecting the proper nose length guarantees efficient heat management and prevents fouling or overheating. The nose length is critical for matching the spark plug to the engine’s thermal needs, ensuring optimal performance.

When dealing with components such as the oil pressure relief valve, proper cleaning and maintenance of surrounding areas using degreaser or brake cleaner can help maintain optimal engine performance.

Employing specific design features, hot spark plugs maximize heat retention to maintain peak firing tip temperatures essential for efficient combustion. They reduce the insulator-metal contact area, limiting heat transfer to the metal shell and preserving heat within the ceramic core. This principle is comparable to how oils with higher friction indexes retain performance under demanding conditions.

Additionally, a longer heat flow path traps thermal energy inside the insulator, functioning as a thermal timing mechanism that sustains self-cleaning temperatures above 500°C.

This design ensures the tip temperature remains within the optimal temperature range to prevent fouling and pre-ignition. The insulator legs are shaped to minimize exposure to cooling metal housing and combustion gases, further conserving heat.

Hot plugs also expose more ceramic at the firing tip, reducing conductive losses to the outer body. Finally, a larger gas pocket capacity insulates the firing end, preventing rapid temperature drops and maintaining consistent heat retention, especially under low-speed conditions where fouling risks increase.

Understanding the thermal dissipation rate of hot spark plugs reveals how their design controls heat retention to optimize combustion. Hot plugs feature a longer, thinner insulator nose, creating an extended heat flow path that slows conduction to the metal shell and cylinder head.

This design minimizes heat loss, maintaining firing end temperatures above 500°C for effective self-cleaning and preventing fouling. Key factors include:

These elements collectively sustain elevated tip temperatures, essential for low-heat engines, while preventing rapid cooling that cold plugs favor for high-heat environments. Selecting the correct heat range ensures the spark plug operates within its optimal temperature range, preventing fouling or pre-ignition caused by improper thermal balance.

Have you ever noticed that cold spark plugs have a shorter insulator nose? This clever design helps accelerate heat transfer away from the firing tip. This shorter thermal path is crucial for improving the spark plug’s ability to manage heat dissipation efficiently.

By doing this, they create a shorter thermal path, allowing for rapid heat dissipation through both the insulator and the metal shell.

Plus, by minimizing the porcelain exposure inside the plug, these spark plugs effectively keep the tip temperature cooler, even in high-stress conditions. It’s pretty fascinating how engineering can enhance performance like this, don’t you think?

Cold spark plugs are typically used in high-performance engines because they reject heat quickly and help prevent overheating during intense operation.

When you examine cold spark plugs, their shorter insulator noses stand out as a key design characteristic that directly influences heat dissipation. The reduced length means heat travels a shorter distance from the center electrode to the shell, enhancing thermal transfer efficiency.

This design prevents overheating under high-load conditions, essential for boosted or supercharged engines. Key features include:

Cold spark plugs excel at rapid heat dissipation by optimizing the heat transfer path from the center electrode through the insulator nose to the metal shell. This efficient heat management helps prevent engine overheating caused by excessive electrode temperatures.

They feature a shorter heat path than hot plugs, accelerating thermal conduction to the engine casing and coolant. A thick insulator nose enhances heat rejection by shortening effective heat retention, promoting rapid cooling under load.

High thermal conductivity materials, including copper-core electrodes, improve heat flow. A strong bond between insulator and shell secures efficient transfer. This design is particularly important in high-temperature risk situations to prevent overheating.

The insulator tip’s reduced projection relative to the shell end minimizes heat buildup, enabling faster conduction to the cylinder head. This design prevents excessive electrode temperatures, reducing pre-ignition risk and sustaining performance in high-load, high-compression conditions such as boosted engines and advanced timing.

Although hot spark plugs operate at higher temperatures, they’re essential for engine conditions where maintaining peak combustion heat prevents fouling and guarantees efficient performance.

You’ll rely on hot plugs when your engine runs in environments or scenarios that challenge combustion stability and carbon deposit management. Consider these key conditions:

While hot spark plugs suit engines operating under lower thermal loads to prevent fouling, engines subjected to intense heat and high stress require plugs with a colder heat range.

You’ll need cold plugs for high-performance or racing engines running combustion temperatures between 2500-3000°F, especially with high RPMs or forced induction like superchargers. This is because colder plugs dissipate heat faster, reducing the risk of pre-ignition caused by excessive insulator temperatures.

Cold plugs dissipate excess heat from high compression ratios, turbocharging, nitrous oxide systems, and lean air/fuel mixtures that elevate cylinder temperatures and risk pre-ignition.

Heavy-duty engines under frequent heavy loads, such as towing or sustained high-speed operation in hot climates, also benefit from cold plugs to maintain thermal balance. Their thicker electrodes resist glowing and electrode melting, ensuring reliable spark delivery under extreme combustion heat and preventing detonation in lean-tuned setups.

Using hot spark plugs can really put your engine at risk. One of the main issues is overheating and pre-ignition.

When these plugs get too hot, they can create glowing spots that might ignite the air-fuel mixture way too soon. This early combustion causes extremely high temperatures and pressures that can damage pistons within just a few cycles, leading to catastrophic engine failure pre-ignition damage.

And that’s not good! It can lead to severe pressure spikes that could potentially damage your pistons in just a matter of moments.

But that’s not all. You might also experience misfires and electrode glazing, which can really mess with your combustion efficiency. This might leave you with rough idling and even increased emissions.

When a spark plug’s heat range is incorrect or engine conditions push combustion temperatures too high, the plug can overheat and trigger pre-ignition.

You risk the firing end exceeding 800°C, turning it into a premature ignition source before the spark fires. This causes abnormal combustion, damaging the engine through pressure spikes and piston ring wear. Regular inspection helps detect overheating early, allowing timely intervention to avoid severe engine damage.

Watch for these key signs:

To prevent this, make sure you select the proper heat range and maintain correct ignition timing, air/fuel mixture, and cooling system function. Improper spark plug gap can also contribute to overheating by causing misfires and increased engine temperatures, so always ensure the gap meets manufacturer specs.

Hot spark plugs can lead to misfires and glazing problems that undermine engine performance and reliability. When plugs run excessively hot, they retain heat that prevents self-cleaning, causing insulator glazing and deposit buildup.

This glazing disrupts spark efficiency, delaying combustion timing and triggering misfires. Misfires also stem from incorrect spark plug gaps, faulty ignition coils, or damaged wires, but hot plugs exacerbate these issues by promoting abnormal burning and fouling. A faulty spark plug or related ignition components often cause these short misfires and engine stuttering.

Consequences include power loss, rough idling, reduced acceleration, and higher exhaust temperatures due to incomplete combustion. Diagnostic signs you’ll notice are check engine lights, engine vibrations, and black exhaust smoke from rich fuel mixtures.

To prevent these problems, maintain proper plug heat ranges, inspect plugs regularly, make sure correct gaps, and avoid prolonged low-speed driving that encourages glazing. Monitoring the exhaust temperature sensor can also help detect when abnormal heat levels indicate incomplete combustion caused by misfires.

Although cold spark plugs are designed to operate at lower temperatures, they can cause significant issues if used improperly. When the tip temperature drops below 930°F, carbon buildup prevents proper deposit burn-off. This leads to fouling and reduced spark intensity. Cold weather conditions also increase ignition demand, making the spark strength more critical for reliable starts.

Fouling results in misfires, rough idling, and poor fuel economy. Additionally, cold plugs exacerbate starting difficulties, especially in cold weather, by weakening sparks and causing delayed ignition. Finally, cold plugs increase the risk of corrosion and uneven cylinder temperatures due to condensation and heat absorption.

Key risks to take into account:

Since ignition timing directly controls when the spark plug fires within the combustion cycle, it markedly affects the plug’s operating temperature. Advancing timing increases combustion temperature and plug heat, about 18-20°F per degree at idle, risking pre-ignition and plug tip glowing red beyond safe limits.

Retarding timing lowers plug temperature but may cause incomplete combustion and overheating. Proper timing balances combustion efficiency and plug temperature within the optimal 500°C–850°C range.

| Ignition Timing | Spark Plug Temperature Effect | Combustion Impact | Engine Performance |

|---|---|---|---|

| Advanced | Raises 18-20°F per degree | Increases combustion heat | Higher power at high RPM |

| Retarded | Lowers temperature | Delays combustion | Reduced power, higher fuel use |

| Excessive Advance | Overheats plug tip | Risk of detonation | Misfire, glaze formation |

| Excessive Retard | Causes incomplete combustion | Heat in exhaust | Engine overheating |

Adjusting ignition timing influences spark plug temperature, but selecting the correct heat range for your spark plug plays a fundamental role in maintaining ideal operating temperatures.

Proper spark plug heat range is key to maintaining optimal combustion temperatures beyond just ignition timing adjustments.

You’ll want to base your choice on engine demands and environmental factors. Consider these key points:

Spark plug heat ranges directly impact your fuel efficiency by influencing combustion quality. Choosing a hotter plug helps burn off deposits during low-speed driving, preventing misfires and improving mileage.

Conversely, a colder plug dissipates heat faster, preventing pre-ignition in high-performance engines but may cause fouling and reduce MPG at light loads.

Using the correct heat range for your driving style and engine guarantees peak combustion, minimizing fuel waste and maximizing efficiency.

Think of your spark plug’s heat range as the thermostat for combustion cleanliness. Yes, it impacts engine emissions directly.

Using a plug too hot causes detonation and fouling, raising HC and NOx levels. Too cold leads to carbon buildup and misfires, increasing unburned fuel emissions.

Choosing the right heat range optimizes combustion, reduces misfires, and lowers CO2, HC, and NOx emissions. This ensures efficient, cleaner engine performance.

Different spark plug heat ranges don’t directly influence your engine’s start-up time. The heat range optimizes plug temperature during operation but doesn’t affect ignition timing or fuel mixture critical for starting.

While fresh plugs might slightly improve power, they won’t speed up start-up markedly. Your engine’s tune, not plug heat range, governs ignition behavior at start.

You might think heat range dictates replacement intervals, but it’s actually the plug’s material that sets the schedule. Copper plugs need changing every 30,000 miles, while platinum and iridium last up to 100,000 miles.

Heat range affects performance and longevity indirectly, so stick to your manufacturer’s recommendations. If you notice misfires or rough idling sooner, replace plugs early regardless of heat range to maintain peak engine function.

You won’t find specific spark plug heat ranges designed exclusively for electric or hybrid vehicles. Hybrids still use conventional gasoline engines, so you select plugs based on standard heat range criteria.

Manufacturers specify OEM heat ranges considering hybrid engine cycles, like Atkinson, and electric assist. Pure electric vehicles don’t need spark plugs at all, making heat range irrelevant for their propulsion system.

Focus on the gasoline engine’s needs when choosing plugs in hybrids.

Choosing the right spark plug heat range is like tuning a guitar string: too tight or too loose, and the performance suffers. Imagine driving with a hot spark plug in a cold engine; it’s like playing out of tune, risking pre-ignition.

Conversely, a cold spark plug in a high-heat environment can cause fouling, much like a slack string muffling the sound. By matching heat range precisely to your engine’s needs, you guarantee peak combustion and longevity.