Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

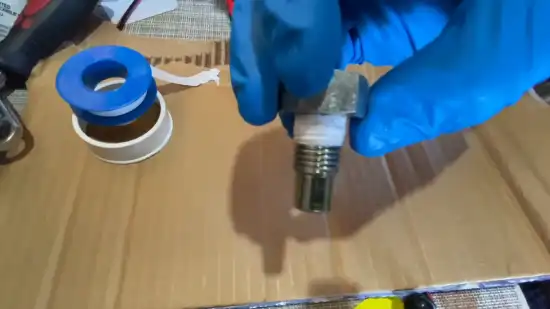

Automotive enthusiasts and DIY mechanics have debated using Teflon tape, specifically white PTFE tape, for sealing oil drain plugs. The use of Teflon tape in plumbing and various fuel line connections has been widely accepted, but its suitability for oil drain plugs remains controversial.

In my research, Teflon tape is unsuitable for high temperatures and pressures, which are common in engine operations. It lacks the lubrication properties necessary for a smooth and easy removal of the drain plug.

Using Teflon tape can also potentially damage the threads on the drain plug, leading to leaks and other complications.

Here, I will explain why using Teflon tape on your oil drain plug can cause more harm than good for your vehicle engine.

I would advise against using Teflon tape on oil drain plugs in your vehicle engine for several reasons. Here are most of the reasons I found:

Teflon tape is inadequate for the high temperatures and pressures in a vehicle engine’s oil system. The tape isn’t designed to withstand the extreme conditions present in an engine’s oil system, and as a result, it can deteriorate over time.

When exposed to the heat generated within the engine, the tape can break down, leading to leaks and potential damage to the engine. Additionally, the high pressure within the oil system can cause the tape to compress and become less effective at sealing the drain plug.

Using Teflon tape on an oil drain plug can lead to insufficient lubrication, potentially causing damage to the plug or threads on the oil pan.

Unlike traditional gaskets or washers, Teflon tape doesn’t provide the necessary lubrication for a proper seal. When the plug is tightened, the tape can become compressed and thin, resulting in metal-to-metal contact between the plug and the oil pan threads.

This lack of lubrication can lead to increased friction, making it difficult to remove the oil drain plug in the future. Additionally, the lack of lubrication can cause the threads to wear down or become stripped, compromising the integrity of the oil pan.

To avoid potential thread damage, it’s important to refrain from using Teflon tape on the oil drain plug in your vehicle engine. Using Teflon tape can result in over-tightening of the drain plug. This can strip or cross-thread the threads in the oil pan. In my understanding, this can lead to leaks and further engine damage.

Teflon tape is generally used for sealing water and gas connections because it provides an effective barrier against leaks. However, when it comes to the demanding conditions of an oil drain plug, Teflon tape falls short.

The oil system in your vehicle operates at elevated temperatures and pressures. Consequently, this can cause the Teflon tape to degrade and fail over time. This can lead to oil leakage and potential damage to your engine.

I prefer not to use Teflon tape on oil drain plugs in your vehicle engine due to its inadequate sealing mechanism. While Teflon tape can provide some level of sealing, it isn’t designed to contribute to the sealing mechanism of oil drain plugs effectively.

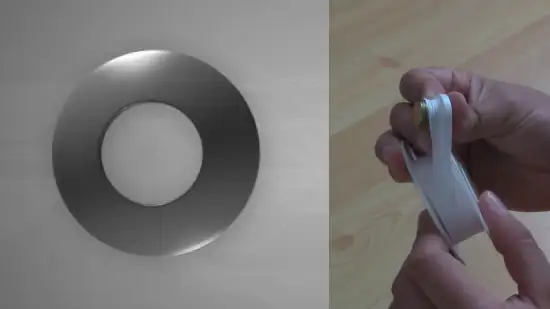

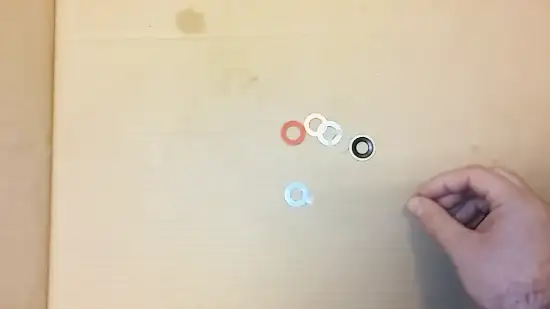

Oil drain plugs are engineered to create a seal through the thread itself, often with the help of a gasket or washer. Teflon tape doesn’t offer the same level of reliability and may not provide a secure seal for all oil drain plug sizes, leading to potential oil leaks.

When the tape deteriorates over time, it can break into small pieces that can easily find their way into the oil system. Once inside, these fragments can block the flow of oil, leading to inadequate lubrication and increased friction.

This can result in excessive heat generation and wear on vital engine components, such as bearings and pistons. According to my knowledge, the tape fragments can interfere with the proper functioning of the oil pump, causing further damage.

When sealing oil drain plugs in your vehicle engine, Teflon tape isn’t suitable for repeated use. As far as I know, Teflon tape is typically a single-use sealing method. Each time the oil is changed, the tape should be reapplied, which can be inconvenient and costly in the long run.

Additionally, Teflon tape can become difficult to remove after multiple uses, resulting in time-consuming and frustrating maintenance.

According to my findings, Teflon tape is generally not recommended for transmission fluid drain plugs.

Top-rated gear oil or transmission fluid drain plugs often have specific requirements, such as crush washers or O-rings. These components are designed to withstand high temperatures and different pressures associated with transmission fluid.

Using Teflon tape instead of the recommended components may result in leaks or other issues.

Teflon tape may interfere with the magnetic properties of the drain plug, which are designed to attract and collect metallic debris. This can hinder the plug’s ability to identify potential engine issues effectively.

Therefore, I recommended choosing alternative sealing methods that do not interfere with the magnetic properties of magnetic oil drain plugs when using Teflon tape.

In my final opinion, using Teflon tape on engine oil drain plugs in your vehicle is a big no-no. It may seem like a quick fix, but it can lead to disastrous consequences.

Teflon tape isn’t designed to handle the high temperatures and pressures of engine oil. It can easily deteriorate and cause leaks, putting your engine at risk.

Stick to using the appropriate gaskets or crush washers recommended by your vehicle’s manufacturer for a secure and leak-free oil change. Sealing oil drain plugs and avoiding Teflon tape contribute to the long-term health and performance of your engine, preventing oil leaks.