Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

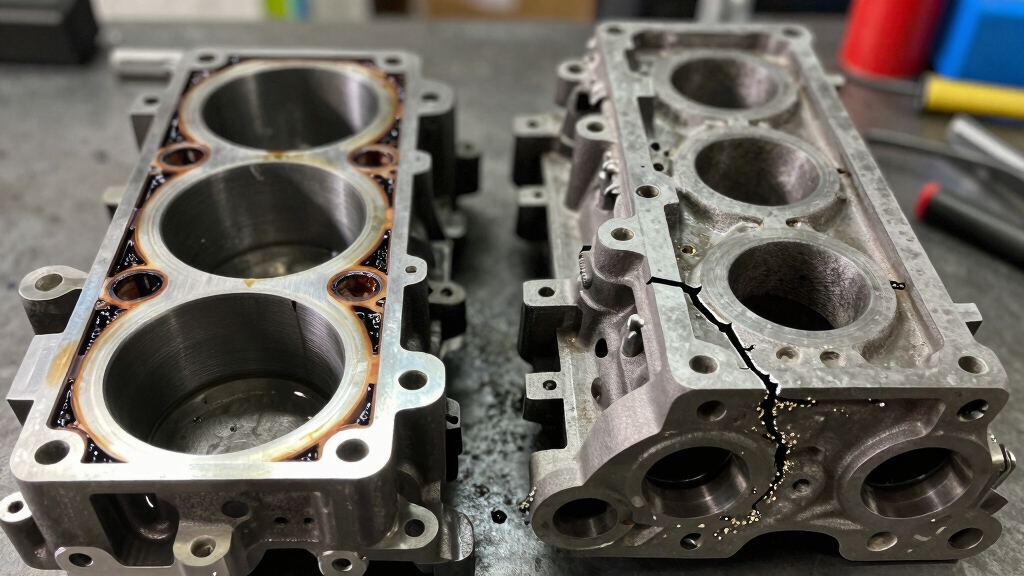

You’ll want to know that a blown head gasket seals the combustion chamber from coolant and oil passages. A cracked engine block involves structural damage to the engine’s core.

Both cause overheating and fluid leaks, but a blown gasket mainly results in coolant-oil mixing and compression loss. In contrast, a cracked block leads to persistent coolant leaks and engine overheating with visible cracks.

Repair costs and complexity differ markedly depending on which issue you face. Exploring their causes and diagnostics can clarify your next steps.

| Aspect | Blown Head Gasket | Cracked Engine Block |

|---|---|---|

| Primary Cause | Overheating or gasket failure | Severe overheating or engine stress |

| Common Symptoms | White exhaust smoke, coolant loss, overheating | Coolant mixing with oil, persistent leaks, misfires |

| Severity Level | Serious but often repairable | Critical and usually irreversible |

| Repair Complexity | Moderate to high labor | Extremely complex or impossible |

| Typical Repair Cost | Lower than block damage | Very high or engine replacement |

| Vehicle Drivability | Limited but sometimes possible short-term | Unsafe to drive |

| Long-Term Impact | Recoverable with timely repair | Permanent engine damage |

Although often overlooked, the head gasket plays a critical role in your engine by sealing the combustion chamber from the cooling system and oil passages.

The head gasket is vital, sealing the combustion chamber from cooling and oil systems to ensure engine integrity.

It sits between the cylinder head and engine block, preventing pressure leaks between cylinders and maintaining compression and fluid separation.

When the head gasket fails, often due to overheating, age, or poor installation, coolant, oil, and combustion gases can mix, impairing engine function. The typical operating temperature for an engine is around 200–225 °F, and sustained temperatures above approximately 240 °F can stress the gasket and cooling system, increasing the risk of failure engine operating limits.

This contamination often leads to milky oil, a sign of coolant mixing with engine oil and a serious symptom of gasket failure. You’ll notice symptoms like rapid temperature rise, white steam, coolant loss without external leaks, and milky oil indicating fluid contamination.

Performance issues include misfires, power loss, rough idling, and knocking from compression loss. Detecting these signs early helps prevent severe damage, as the gasket’s integrity is essential for maintaining engine efficiency and preventing cross-contamination of essential fluids.

While a blown head gasket often signals a serious engine issue, a cracked engine block presents a more severe and complex challenge. You face structural damage causing coolant and oil intermix, compression loss, and persistent overheating.

The engine block is the main engine part supporting pistons and crankshaft, so any cracks severely compromise engine integrity. Removal of components to access the engine block and perform repairs can be challenging due to limited access around the engine.

Detecting cracks requires pressure tests, dye inspections, and OBD2 diagnostics. The consequences escalate quickly, from rough running to complete engine failure.

| Symptom | Diagnostic Method | Severity Impact |

|---|---|---|

| White exhaust smoke | Pressure and dye tests | Loss of engine power |

| Milky oil | Visual and dye inspections | Contaminated lubrication |

| Overheating | OBD2 fault codes | Increased fuel consumption |

| Misfires | Endoscope inspection | Cylinder temperature imbalance |

| Warning lights | Magnetic crack detection | Potential full engine replacement |

Understanding these factors helps you assess the urgent need for repair or replacement. Proper procedures and careful handling during repair are critical for engine health and longevity.

Because engine integrity relies heavily on proper sealing and material strength, understanding the common causes and symptoms of blown head gaskets and cracked engine blocks is essential for accurate diagnosis.

Blown head gaskets often result from overheating, engine knock, improper installation, age, or incorrectly torqued head bolts, leading to seal failure. The head gasket ensures maximum compression by sealing the cylinders between the engine block and cylinder head.

Symptoms include white exhaust smoke, bubbles in the radiator, milky oil from coolant contamination, coolant loss without leaks, and rough idling. Regular monitoring of engine temperature and coolant levels can help detect gasket issues before severe damage occurs.

Cracked blocks arise from severe overheating, freezing coolant expansion, or manufacturing defects, causing structural damage. You’ll notice visible cracks, persistent coolant leaks, continuous overheating, and severe coolant contamination.

While both exhibit coolant and oil mixing, gasket failure affects the seal interface, whereas block cracks compromise the engine’s structural integrity. This makes gasket issues more common and less costly to repair.

When diagnosing engine issues like a blown head gasket or cracked block, you must rely on a combination of specialized tests and inspections to pinpoint the exact fault.

Start with a block tester to detect combustion gases in the cooling system; a color change from blue to yellow confirms exhaust gas presence but doesn’t specify the cause. The block tester uses a blue fluid that changes color when exposed to combustion gases, providing a simple and inexpensive initial test.

Additionally, ensuring proper oil circulation can help determine if the engine’s lubrication system is functioning correctly, which may be affected by such faults. Conduct a cooling system pressure test to identify leaks, listening for air rushing and observing pressure drops.

Use a compression test to detect cylinder sealing issues, where adjacent low compression suggests gasket failure. Visually inspect for coolant pooling, oil contamination, or visible cracks in the block.

For conclusive results, professionals may perform head removal and cylinder leak tests. Accurate diagnosis requires correlating these methods systematically to differentiate overlapping symptoms.

If you want to address a blown head gasket or a cracked engine block effectively, you need to understand the distinct repair methods and their associated costs.

For a blown head gasket, expect full disassembly, cylinder head resurfacing, and gasket replacement, with labor dominating 8–12 hours. Costs average $2,400–$3,200 but can escalate to $6,000 with complex engines or added parts.

Since labor cost variation is the largest driver of total expense, getting multiple repair quotes can help manage costs. Additionally, addressing leaks promptly is crucial as ignoring them can lead to potential health risks and further mechanical damage.

Cracked engine blocks require more intensive solutions: minor cracks might see welding or sleeve installation, but severe damage typically demands engine block replacement or a full engine swap. These repairs often exceed $5,000, with labor surpassing 20 hours.

Given the expense and complexity, weigh repair costs against vehicle value. Head gasket repairs extend engine life, while cracked blocks often justify engine replacement for reliability.

Imagine your engine as a sealed orchestra where every cylinder plays its part.

A blown head gasket lets the music leak: compression escapes or coolant invades a cylinder, causing your engine’s harmony to falter.

Yes, a blown head gasket can cause misfires by disrupting combustion through compression loss or coolant contamination.

You’ll notice rough idling, power drops, and misfire codes.

Diagnosing requires detecting these leaks and verifying combustion integrity precisely.

You shouldn’t drive with a cracked engine block for more than a few minutes to a couple of days at most, depending on the crack’s severity.

Beyond 100 miles, you risk catastrophic failure due to coolant loss, overheating, and oil contamination.

Short trips might be possible but aren’t safe, as heat and pressure rapidly worsen the crack.

Stop driving immediately and tow your vehicle for professional assessment and repair.

Absolutely, some car models are practically magnets for head gasket failure!

If you own a 2015 Buick Encore or a 2011 BMW 3 Series, your risk skyrockets, especially past 75,000 miles.

Subaru’s EJ25 engines before 2003 also have a notorious reputation.

These failures stem from engine design flaws and material stresses under heat and pressure.

Knowing this helps you anticipate repairs and possibly choose more reliable alternatives like Toyota or Honda models.

You can use coolant additives to help prevent minor head gasket leaks by sealing micro-cracks early and stabilizing coolant, reducing gasket damage risk.

However, they won’t stop structural damage like cracked blocks caused by overheating or defects. Additives temporarily mask symptoms but don’t repair cracks or prevent block failure.

Relying solely on them risks missing serious issues requiring mechanical inspection and repair for lasting engine health.

Yes, a head gasket can fail without overheating symptoms. You might notice subtle signs like coolant level drops, milky oil, or bubbles in the radiator without temperature spikes.

Internal leaks allow coolant to mix with oil or enter combustion chambers silently, evading typical overheating cues. To detect this, you’ll need chemical tests or compression checks, as visual inspections and normal engine performance don’t reliably reveal early gasket failures.

When your engine faces issues, distinguishing between a blown head gasket and a cracked block is like identifying a leak in a pipe versus a crack in its foundation. Both disrupt function but demand different repairs.

By accurately diagnosing the problem through symptoms and tests, you can avoid costly mistakes. Understanding these differences helps you make informed decisions, ensuring your engine’s integrity and performance are restored efficiently and effectively.