Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

To get rid of hemi tick noise, start by checking and tightening exhaust manifold bolts and replacing any cracked gaskets. Inspect hydraulic lifters and valve train components for wear, cleaning or replacing them as needed.

Maintain ideal oil pressure with regular full synthetic oil changes and quality filters. Consider upgrading your oil pump for better flow. Address leaks promptly and avoid aggressive driving until warm.

If the tick persists, a deeper diagnosis is needed to identify underlying issues, which you can explore further here.

Although several factors can cause the distinctive ticking noise in Hemi engines, the most common sources include exhaust manifold issues, hydraulic lifter behavior, lifter and roller wear, MDS system effects, and fuel injector operation.

Common ticking in Hemi engines often stems from exhaust manifolds, lifters, MDS, or fuel injectors.

You’ll find broken or loose exhaust manifold bolts often cause external ticking, especially due to high temperatures. Fixing these is relatively inexpensive. Engine heat can cause these bolts to break before 80,000 miles, leading to ticking noises.

Hydraulic lifters create a brief rattle on cold starts when oil refills the plungers. This is usually harmless if it disappears quickly. Proper oil filtration is essential to maintain lifter functionality and reduce ticking noises.

Lifters with failing needle roller bearings generate irregular ticking at operating temperature, signaling potential camshaft damage. The Multi-Displacement System’s cycling may disrupt lifter lubrication, accelerating wear if oil maintenance lapses.

When diagnosing engine ticks, you need to distinguish between normal operational sounds and those signaling mechanical issues.

Normal ticks, such as lifter or injector noises, are rhythmic, rapid, and often fade as the engine warms or RPMs rise. They correlate with lower oil pressure at cold start and resemble a steady “sewing machine” chirp, typically disappearing within 60-90 seconds.

Maintaining proper lubrication through regular oil changes can help prevent abnormal ticking noises. Additionally, using high-quality oil with appropriate additives can reduce wear and noise.

In contrast, problematic ticks like rod knocks are louder, erratic, and worsen with engine load or acceleration, persisting even when warm. They often coincide with low or unstable oil pressure and don’t diminish over time.

Monitoring the tick’s behavior relative to oil pressure, engine temperature, and load helps you accurately identify if the noise is benign or indicative of mechanical failure needing prompt attention.

To minimize Hemi tick noise effectively, you must prioritize consistent oil and lubrication maintenance. Change your engine oil every 5,000 miles using full-synthetic 5W-30 or 0W-40 oils and high-quality filters to ensure proper lifter lubrication.

Mobil 1 Extended Performance, with its higher concentrations of anti-wear additives, can provide enhanced protection for critical engine components. Regularly removing the intake manifold and inspecting the VVT solenoid screen for metal debris can help detect early camshaft and lifter wear.

Upgrade to a Hellcat high-pressure oil pump if possible and avoid extended idling to maintain oil pressure. Regularly inspect lifters, exhaust manifolds, and VVT solenoids, addressing minor leaks and component wear promptly to reduce ticking.

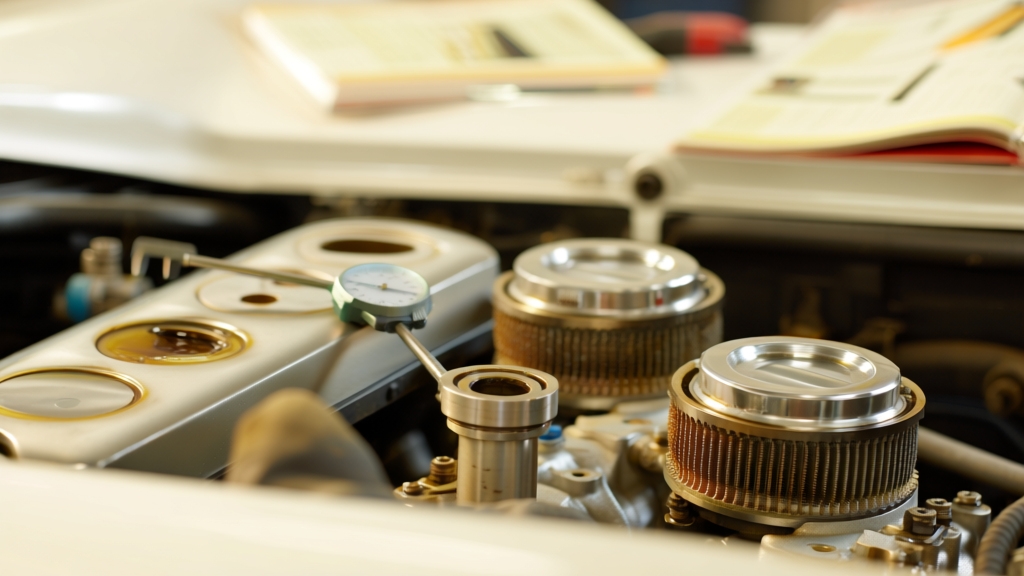

Alright, let’s dive into diagnosing that tick! First up, grab a mechanic’s stethoscope. You’ll want to use it to pinpoint where that annoying tick is coming from. Focus on the valve covers, the exhaust manifold, and those injector areas. Using fuel injector cleaners can sometimes help reduce ticking caused by deposit buildup.

As you listen, pay close attention to the tick patterns. Notice things like consistency, pitch, and intensity. These details are super helpful to figure out if it’s lifter noise or an exhaust leak. Use the stethoscope on the engine block to determine if the tick is internal or external.

Oh, and don’t forget to inspect the exhaust manifold flange! Look for any cracks or loose studs there; it could really help confirm if the ticking is due to gas leaks.

Happy diagnosing!

Although diagnosing engine tick noises can be challenging, using a mechanic’s stethoscope offers a precise method to localize the source of the noise on the engine block. Selecting the correct engine oil with proper viscosity grades can also influence the presence and severity of tick noises.

Place the probe on suspected areas like valve covers, lifter valley, camshaft lobes, and exhaust manifold studs while the engine idles at normal temperature. Persistent ticking that lasts beyond initial startup may indicate hydraulic lifter failure, which requires careful diagnosis.

Test both sides separately to isolate the tick’s origin. A steady tick near exhaust bolts indicates an external leak, while irregular clicks in the valvetrain point to lifter or camshaft issues.

Rotate the engine to confirm mechanical correlation. The stethoscope’s effectiveness hinges on your ability to discern subtle auditory differences and minimize ambient noise, often requiring removal of engine covers.

This non-invasive approach enables accurate identification without immediate disassembly, streamlining diagnosis of the classic “Hemi tick.”

After localizing the noise with a mechanic’s stethoscope, analyzing the tick patterns gives you critical clues about the underlying cause.

You’ll differentiate between exhaust leaks, lifter failures, and internal engine damage by focusing on timing, consistency, and response to temperature or RPM changes. Understanding the role of the oil pressure sensor can also help in diagnosing issues related to engine lubrication and performance.

This analytical approach lets you pinpoint the fault source accurately.

Focusing on the exhaust manifold is critical when diagnosing engine tick noises, as leaks or damage here frequently cause the issue.

Begin with a thorough visual inspection under strong lighting, checking for hairline cracks, soot stains, or blackened areas that signify gas leaks. Consider the compatibility with older vehicles when evaluating the condition, as older engines may have different wear patterns affecting the manifold.

Remove heat shields to expose hidden damage and assess the gasket’s condition for wear or blowout. Use a straightedge to detect warpage on cleaned surfaces; light passing beneath indicates unevenness compromising the seal.

Verify all bolts and studs are present, properly torqued, and free of corrosion. Missing or broken mounting studs can weaken system stability and contribute to leaks. Employ diagnostic tools like smoke tests to reveal subtle leaks and infrared pyrometers to identify hot spots.

Finally, inspect adjacent components, including downpipe connections, heat shields, and mounts, for damage or looseness that may mimic manifold-related ticking. Ensuring proper maintenance intervals can reduce such issues and improve overall engine performance.

When you encounter persistent ticking noises in your Hemi engine, targeted repairs on key components like the exhaust manifold, hydraulic lifters, and valve train become essential.

Focus on these effective repair options to eliminate ticking:

Concentrate on targeted repairs to effectively stop ticking noises in your Hemi engine.

These precise interventions will markedly reduce or eliminate persistent tick noises in your Hemi engine.

Although persistent ticking can often be resolved with repairs, preventing future engine noise requires diligent maintenance and component care.

You should change your oil every 5,000 miles using full synthetic 5W-30 or 0W-40 oil. Choosing a motor oil with advanced additive technology can further enhance engine performance and protection.

Install high-quality oil filters to maintain lifter lubrication and reduce sludge.

Upgrading to a Hellcat high-pressure oil pump (post-2009 models) or a high-volume pump (pre-2009) improves oil flow and pressure, mitigating lifter collapse. This is critical because the camshaft is second to get oil and requires consistent lubrication to prevent premature wear.

Avoid extended idling and aggressive driving before warm-up.

Maintain consistent RPMs during engine warm-up to preserve oil circulation.

Routinely inspect and torque valve train components.

Replace worn timing parts and promptly address exhaust manifold leaks.

Early detection through noise diagnosis and oil analysis helps identify issues before failure, ensuring your Hemi’s valve train remains quiet and reliable.

Maintaining preventive measures can minimize Hemi tick noise, but certain symptoms signal the need for professional mechanic intervention. You should seek expert diagnosis if:

Prompt consultation prevents costly damage and ensures precise identification of complex internal engine problems.

Certain fuels won’t directly reduce Hemi tick noise because that sound mainly stems from mechanical causes like lifter operation or exhaust leaks.

However, using high-quality fuels with proper detergents and additives can improve injector cleanliness and combustion efficiency, which may indirectly minimize some injector-related ticks.

Altitude doesn’t directly change your Hemi engine’s ticking sounds; it’s like background static that stays constant.

Ticking mainly stems from mechanical factors like lifters or exhaust leaks, unaffected by air pressure or oxygen levels.

While altitude shifts air density, causing subtle combustion changes, these don’t alter the core ticking noise.

You might perceive differences due to thinner air, but the tick’s origin remains firmly rooted in engine mechanics, not elevation.

Yes, you can find aftermarket products designed to address Hemi tick noise.

Additives like LiquiMoly MoS2 and Schaeffer’s moly aim to improve lubrication and reduce ticking, though their effectiveness varies.

Upgraded oil pumps, especially Hellcat models, enhance oil flow to lifters, preventing wear.

You might also consider aftermarket exhaust manifold kits to fix leaks causing noise.

Additionally, switching to premium synthetic oils like Redline 5W-20 can help minimize ticking sounds.

Engine tuning directly impacts Hemi tick occurrence by altering oil pressure, flow, and temperature, which affects hydraulic lifter function.

If you adjust parameters that thin oil or change idle RPM, you risk insufficient lifter lubrication and increased ticking.

Improper management of cylinder deactivation timing (MDS) can worsen lifter noise.

Also, aggressive tuning raising engine heat or load can accelerate lifter wear, so you must consider oil maintenance alongside tuning for ideal tick control.

Yes, cold weather can worsen Hemi engine ticking because thicker oil delays proper lubrication of lifters and camshaft components at startup.

You’ll notice ticking more during cold starts as metal contracts, potentially loosening exhaust bolts or creating gaps.

However, this ticking usually diminishes once the engine warms and oil viscosity normalizes.

You should monitor if ticking persists after warm-up, as that could indicate more serious mechanical issues requiring inspection.

Tackling that Hemi tick noise is like tuning a finely crafted instrument. Every click signals a potential misstep or harmony. By diagnosing the root cause with precision and maintaining your engine vigilantly, you can silence that persistent tick before it crescendos into costly damage.

Don’t let the noise echo unchecked; address it methodically. When complexity overwhelms you, call in a professional mechanic to guarantee your engine performs flawlessly and reliably.