Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Proper alignment of the oil pump shaft with the distributor is a critical aspect of maintaining the health and performance of a vehicle’s engine. When the oil pump shaft and distributor are not aligned correctly, it can lead to various issues, from low oil pressure to engine damage.

To align the oil pump shaft with the distributor, you need to prepare the vehicle. Position the engine to its initial orientation and align the oil pump shaft. Drop and seat the distributor into place. Verify the timing of the engine and test the oil pressure.

Here, we will guide you through the step-by-step process of aligning these components. By following our expert advice, you can ensure optimal performance and prevent potential issues caused by misalignment.

To align the oil pump shaft with the distributor in a vehicle engine, several steps must be taken. And ensure the steps are completed correctly.

When aligning the oil pump shaft with the distributor in your vehicle engine, you’ll need the necessary tools and equipment. Ensure the engine is turned off and has cooled down completely before proceeding.

Begin by removing the distributor cap and carefully marking the location of the #1 spark plug wire on the distributor housing. This will help you align the distributor correctly later on.

If available, connect an oil pressure gauge to the oil pressure sending unit to monitor the oil pressure in real time. This is important for ensuring proper lubrication during the alignment process.

Ensure the distributor rotor precisely points at the housing’s #1 spark plug wire once you have prepared the necessary tools and equipment. This initial alignment position is crucial as it ensures that the distributor is ready for installation with the rotor correctly oriented.

To achieve this, rotate the engine by hand until the timing mark on the harmonic balancer aligns with the ‘0’ mark on the timing tab. Then, remove the distributor cap and visually inspect the position of the rotor.

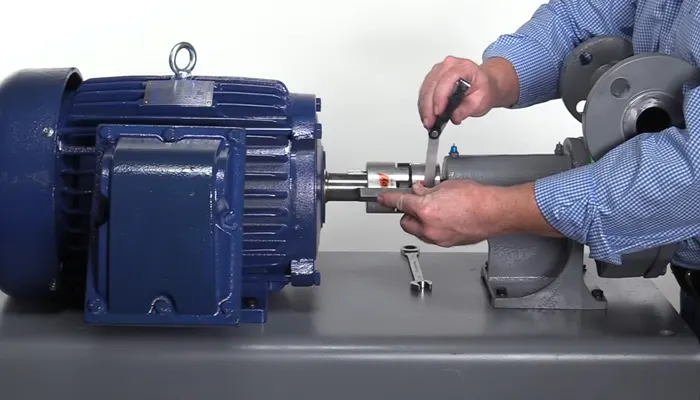

If it isn’t pointing directly at the #1 spark plug wire location, you must rotate the oil pump shaft using a long flat-blade screwdriver until the desired alignment is achieved. Alignments should be made in small steps to ensure accuracy.

Carefully insert the oil pump shaft into the block and align it to the distributor mark. Before fully tightening, first verify that the rotor is still pointing at the desired plug wire location on the distributor cap. The oil pump shaft usually has an index mark that should be aligned with the distributor.

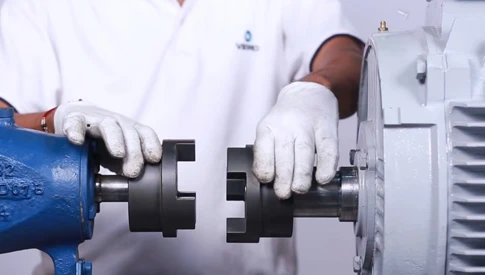

As you carefully insert the distributor into the engine, pay close attention to the oil pump shaft and ensure that the distributor shaft is securely engaged with the camshaft.

With one person holding the distributor in place and maintaining light downward pressure, use a socket wrench to turn the crankshaft bolt by hand. This will coax the distributor into place.

As the engine is turned, the distributor should drop into position when the oil pump shaft aligned precisely with the distributor’s gear. It’s important to turn the engine slowly and stop immediately if any resistance is felt.

Once the distributor is seated, double-check the alignment of the oil pump shaft with the distributor gear to ensure proper engagement.

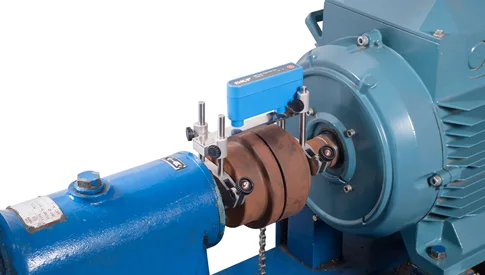

To verify the timing, begin by ensuring that the rotor still points at the #1 spark plug wire location on the distributor housing after seated. This confirms that the distributor is correctly aligned.

Next, check that the distributor housing is securely fixed in the correct position. Any movement or misalignment can lead to incorrect timing.

Once these steps are completed, carefully reinstall the distributor cap. This final step ensures that the distributor is properly sealed and protected.

To ensure accurate alignment of the oil pump shaft with the distributor in your car’s engine, it’s important to test the oil pressure.

Start by running the engine and monitoring the oil pressure gauge, if available. Adequate oil pressure is crucial for proper oil circulation and the overall health of your engine.

If the oil pressure is too low, it can lead to insufficient lubrication, which can cause excessive wear and damage to engine components. On the other hand, if the oil pressure is too high, it can result in unnecessary strain on the oil pump and other parts of the engine.

To fine-tune the oil pump shaft alignment with the distributor in your vehicle engine, gently rotate the distributor until the timing is correct.

If your oil pump shaft is misaligned, you may experience various symptoms that indicate a problem. These include:

Experiencing low oil pressure is a clear indication of oil pump shaft misalignment. When the oil pump shaft isn’t aligned properly with the distributor in a vehicle engine, it can lead to reduced engine oil pressure.

This can result in inadequate lubrication and cooling of engine components, which can cause serious damage over time. On the dashboard, a reading below normal levels on the oil pressure gauge indicates that the oil pump shaft is misaligned.

You may notice abnormal engine noises such as knocking, ticking, or clattering if the oil pump shaft is misaligned with the distributor in your vehicle engine.

When the oil pump shaft isn’t properly aligned, it can result in poor lubrication of the engine components. This increases friction and wear, causing the engine to make unusual noises.

The knocking noise is often described as a repetitive thumping, while the ticking noise can be more like a rapid clicking. Clattering noises typically occur when the engine is under load. These noises are particularly noticeable during cold starts when the engine isn’t fully lubricated.

When your vehicle’s oil pump shaft is misaligned with the distributor, it can result in inadequate lubrication, leading to excessive heat buildup within the engine. This can cause your engine to overheat, which can have severe consequences.

You may notice that the temperature gauge on your dashboard is reading higher than normal or that the engine is emitting more heat than usual. Another symptom is activating warning lights on your dashboard, such as the coolant temperature warning light.

If the oil pump shaft in your vehicle engine is misaligned with the distributor, it can reduce engine performance. Misalignment can cause inadequate lubrication to key engine components, leading to increased friction and decreased efficiency.

Misaligned oil pump shafts cause lower power output as the engine struggles to perform optimally. You may also experience decreased fuel efficiency as the engine works harder to overcome the lack of proper lubrication.

Poor acceleration can also be a symptom, as the engine may struggle to generate the necessary power to quickly increase speed.

Another indication that your vehicle’s oil pump shaft is misaligned is the presence of oil leaks. Misalignment can cause additional stress on the oil pump and other components, leading to leaks from various points in the engine, such as gaskets, seals, and connections.

To identify potential leaks, look for oil puddles or drips under the vehicle. These leaks can result from the misaligned oil pump shaft putting excessive pressure on the engine’s internal components, causing them to fail and allowing oil to escape.

There are three main causes of oil pump shaft misalignment in your vehicle engine.

Depending on the engine design and configuration, specific steps or adjustments may be required to align the oil pump shaft with the distributor. In some engines, the distributor may need to be rotated or adjusted to align with the oil pump shaft, while in others, it may require alignment tools or indicators.

It’s crucial to consult the vehicle’s manual for accurate instructions tailored to your specific make and model. Following the manufacturer’s guidelines will ensure proper distributor alignment and prevent any potential issues with engine performance.

Aligning the oil pump shaft with the distributor in a vehicle engine is a crucial task that ensures the proper functioning of the engine. When executed correctly, it guarantees proper oil circulation and pressure, which is vital for the engine’s well-being.

By recognizing the symptoms of misalignment, such as low oil pressure, engine noise, and reduced performance, we can prevent further damage. Keeping an eye out for signs of misalignment, as outlined in this guide, can ensure the engine’s longevity and reliability, keeping it running smoothly for years to come.