Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

You can expect kerosene stored properly in sealed, cool, and dry conditions to stay good for 3 to 5 years. Sometimes it can last up to 10 years with stabilizers.

Once opened, its quality deteriorates faster, often within 6 months, due to air and moisture exposure causing oxidation and microbial growth. Watch for discoloration, sediment, or foul odors as signs of degradation.

Understanding storage, container choice, and quality monitoring will help you maintain your kerosene’s effectiveness longer and avoid equipment issues.

Although kerosene’s shelf life can vary, it generally remains usable for at least five years when stored properly in approved containers. You should note that manufacturers often recommend a three-year shelf life for unopened containers, while once opened, kerosene’s usability drops to approximately six months.

Industry standards commonly cite five years as the maximum recommended duration, but real-world reports indicate kerosene can remain effective up to ten years if conditions are ideal. You’ll find that kerosene stored in sealed, cool, dry environments tends to outlast stated guidelines.

To maintain fuel integrity, regular inspection and minimizing exposure to air and moisture are vital. Additionally, using additives to prevent oxidation can significantly extend the fuel’s life and preserve quality.

Proper storage conditions and understanding the effects of chemical degradation are crucial for optimizing kerosene longevity. Understanding these typical shelf life parameters helps you manage kerosene storage with precision and safety.

When you store kerosene, several factors directly influence how long it remains effective, including additives, contamination, temperature, and exposure conditions.

Additives like stabilizers inhibit oxidation and sludge formation, but their protective effect wanes over time, especially if the fuel encounters contaminants or temperature shifts.

Water and particulates accelerate degradation by fostering microbial growth and catalyzing chemical breakdown, compromising fuel stability and causing operational issues.

Temperature fluctuations induce condensation, increasing water content, and speed up chemical reactions that form gums and sludge.

Exposure to air and UV light promotes oxidative degradation, generating peroxides and discoloration.

Microbial activity, favored by water presence and nutrient availability, biodegrades kerosene, producing acids and sludge that degrade quality.

Understanding these factors helps you maintain kerosene’s usability and prevents premature spoilage.

Unlike kerosene, automotive fluids such as power steering fluid and transmission fluid have specific formulations to withstand distinct thermal and mechanical stresses in vehicles.

To keep kerosene in top shape, it’s super important to store it in a cool, dry place. This helps reduce the chances of degradation caused by temperature changes and humidity. Selecting storage containers with a high Total Base Number can further improve fuel stability by neutralizing acids.

Since kerosene’s chemical stability is highly sensitive to environmental factors, controlling temperature and humidity during storage is critical to maintaining fuel quality.

You should store kerosene in cool, stable conditions below 25°C to slow chemical degradation and prevent flammable vapor buildup. Its flashpoint typically ranges between 100-150°F, which underscores the importance of avoiding excessive heat during storage.

Proper storage practices also reduce the risk of contamination similar to how proper antifreeze disposal prevents environmental damage. Avoid temperatures above 36°C, which accelerate breakdown and pose safety risks, and below -40°F, where gelling impairs flow.

High humidity increases water condensation inside containers, encouraging microbial growth that degrades kerosene and clogs filters. Moisture also causes sediment formation and corrosion risks.

To reduce these effects, store kerosene in dry, well-ventilated spaces away from dampness and inspect containers regularly to remove water accumulation. Combining temperature stability with humidity control profoundly extends kerosene’s usability and preserves combustion quality.

Although kerosene’s chemical stability depends heavily on environmental factors, the quality of container sealing plays an equally crucial role in preserving fuel integrity. You must ensure containers use fire-safe, chemical-resistant seals capable of withstanding temperature fluctuations from -96°C to 150°C. Choosing seals that comply with FIRE-SAFE standards is essential for safety and regulatory compliance.

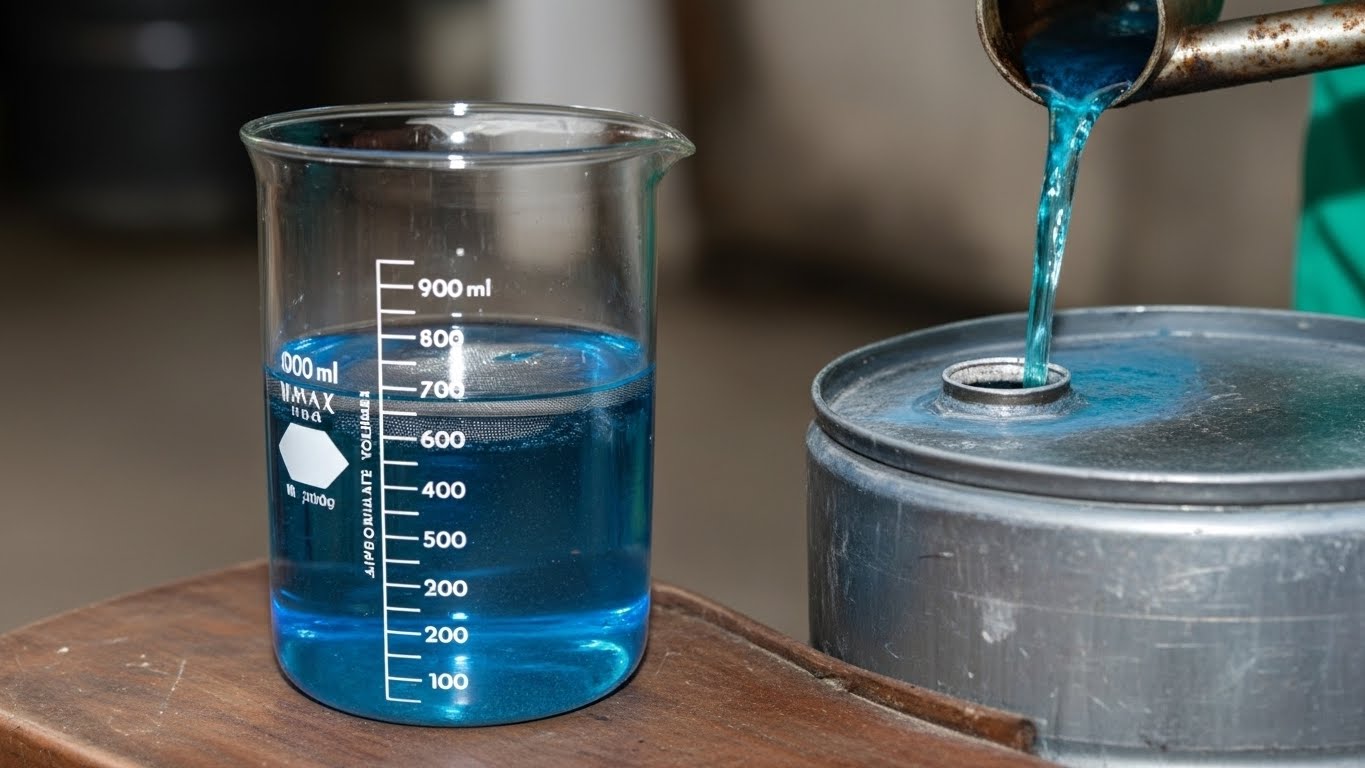

Properly sealed metal drums or plastic no-spill containers minimize air and moisture ingress, markedly slowing oxidation and microbial contamination. You should limit container opening time during dispensing to reduce oxygen exposure, which accelerates fuel degradation.

Additionally, maintaining proper storage temperature and avoiding exposure to extreme cold can prevent issues similar to diesel fuel gelling, which affects fuel quality and engine performance.

Regularly inspect and maintain seals to prevent leaks, rust, and water intrusion that cause emulsification and sediment formation, compromising combustion performance. Employing secondary containment further prevents cross-contamination and environmental pollutants.

Adhering to regulatory sealing standards enhances safety and fuel longevity, making container sealing quality a critical factor in maintaining kerosene’s usability over time.

You can spot degraded kerosene pretty easily if you know what to look for. First off, check the color. If it’s getting darker than usual, that’s a red flag. You might also notice it becoming cloudy or even have some visible sediment floating around.

Cloudiness suggests the presence of water, which can cause microbial growth and damage the fuel’s quality water contamination. Regular inspection and proper storage are crucial to prevent such degradation and maintain fuel efficiency.

But it’s not just about the looks! Pay attention to any strange smells. If it starts to smell sour, pungent, or just off compared to its usual mild scent, that’s another sign something’s not right.

These visual and smell cues really tell you a lot about the chemical changes and contamination that could be impacting the quality of your fuel. Proper handling and storage conditions significantly reduce the risk of fuel degradation.

A clear set of visual indicators can help you identify degraded kerosene before use. First, observe color changes: kerosene that darkens, fades, or shifts to yellowish or brownish hues signals chemical degradation or contamination.

Continuous online monitoring using color measurement scales can provide early detection of such changes, preventing quality issues. Proper oil classification ensures fuel compatibility and longevity by maintaining chemical stability.

Next, check for sediment or particulates settled at the container’s bottom, which indicate microbial growth or impurities. Cloudiness or loss of clarity points to moisture contamination or oxidation, both detrimental to fuel quality.

Additionally, any physical film or slime formation on the surface confirms microbial spoilage, rendering the fuel unsafe. Finally, during combustion, watch for excessive smoke, soot, or irregular flame behavior; these visual signs reflect reduced fuel stability and impaired burning efficiency.

Monitoring these parameters ensures you avoid using compromised kerosene that may damage equipment or reduce performance.

How can you tell if kerosene has started to degrade before relying on visual cues? Odor changes are often the earliest sign.

Fresh kerosene has a characteristic hydrocarbon smell, primarily from volatile alkanes, alkenes, aromatics, and trace sulfur compounds. As it deteriorates, you’ll notice a stronger, more acrid or sour odor.

The volatile hydrocarbons responsible for kerosene’s distinctive scent also contribute to its penetrating and easily recognizable smell. Similar to how motor oils contain ZDDP additives to enhance protection, kerosene’s composition changes can affect performance and safety.

Microbial contamination introduces musty or earthy scents, while chemical breakdown sharpens the hydrocarbon aroma. These odor shifts can indicate oxidation, microbial growth, or water presence, often preceding visible contamination.

You should compare the smell against fresh kerosene annually to detect subtle differences. Strong or unusual odors also serve as important safety warnings, alerting you to potential leaks or health hazards.

When kerosene degrades or becomes contaminated, it directly compromises combustion efficiency and equipment performance. This causes smoky flames, excessive soot, and potential clogging of fuel system components. Both Kirkland and Mobil 1 synthetic oils comply with stringent environmental regulations, highlighting the importance of quality fuel and oil for optimal engine operation.

You’ll notice decreased heat output and increased fuel consumption, which impacts operational costs. Additionally, harmful fumes may be emitted, raising health and safety concerns. To avoid these issues, consider the following effects of using old or contaminated kerosene:

Proper storage in original or approved containers can help maintain kerosene quality for up to 5 years under optimal conditions. Using fresh, properly stored kerosene is essential for ideal performance and safety.

You can actually extend kerosene’s shelf life by using some specific stabilizers and additives. Things like antioxidants, biocides, and corrosion inhibitors are designed to help prevent oxidation, microbial growth, and even metal corrosion.

Now, when it comes to applying these additives, you need to be pretty precise with the dosing. It really depends on your storage volume and the conditions you expect.

This way, you can effectively maintain the integrity of your fuel. PRI-D, for example, treats fuel at a ratio of 1:2,000, making it a highly cost-effective solution. Using fuel stabilizers also helps to prevent phase separation in ethanol-blended fuels during storage.

If you use these additives properly, you’ll find that it guarantees cleaner combustion, reduces deposits, and ultimately gives you a longer usability of your kerosene supply. Pretty handy, right?

What keeps kerosene stable and usable over extended periods? It’s the right combination of fuel stabilizers and additives designed to maintain chemical integrity and prevent degradation.

You’ll encounter several types specifically formulated for kerosene and diesel blends:

Each additive type targets critical degradation pathways. Selecting the correct stabilizer depends on fuel compatibility and storage conditions to maximize kerosene’s shelf life and performance.

Since fuel stabilizers lose effectiveness if added too late, applying them at the point of kerosene storage is essential to maximize preservation.

You should add stabilizers precisely per manufacturer instructions, ensuring complete mixing through shaking or stirring and allowing several minutes for integration.

Using clean, sealed containers and avoiding heat or sunlight during application preserves fuel quality. Larger storage tanks should be equipped with pressure/vacuum relief valves to prevent damage during temperature fluctuations.

Proper additive use inhibits oxidation, microbial growth, gum formation, and corrosion, extending kerosene usability up to 5 to 10 years with annual retreatment.

Dosage accuracy is critical; both under- and overdosing reduce effectiveness or cause issues. Select additives compatible with kerosene, avoiding those formulated solely for gasoline or diesel.

Employ personal protective equipment and handle additives in well-ventilated areas to minimize safety risks. Following these protocols optimizes kerosene stability and engine performance over prolonged storage periods.

Although kerosene is a stable fuel when stored properly, following best practices is essential to preserve its quality and guarantee safety.

You need to manage storage conditions carefully to prevent degradation and hazards.

Adhering to these protocols minimizes fuel deterioration and enhances safety during kerosene storage.

When selecting containers for long-term kerosene storage, you must prioritize materials that resist contamination and prevent vapor loss. High-density polyethylene plastic containers, metal drums, and underground storage solutions each offer unique advantages.

Plastic containers provide chemical resistance and venting features, while metal drums ensure puncture resistance and airtight sealing. Underground tanks support large volumes with environmental safeguards. It is important to use containers specifically designed for fuel storage and clean them thoroughly before use to avoid contamination.

| Container Type | Key Features | Suitable Uses |

|---|---|---|

| Plastic Containers | HDPE, vented caps, dual handles | Small to medium quantities |

| Metal Drums | Steel, sealed lids, corrosion-prone | Bulk storage, commercial |

| Underground Storage Tanks | Corrosion-resistant, monitored | Large-scale, long-term |

Choose containers rated for kerosene, label them clearly, and store away from ignition sources for maximum fuel preservation.

Selecting the right container for kerosene storage sets the stage for maintaining fuel integrity. Ongoing monitoring and testing are necessary to guarantee its quality over time. You should:

This systematic approach ensures kerosene remains stable, safe, and efficient throughout its storage life.

Because kerosene is highly flammable and chemically reactive, you must adhere to strict safety precautions during handling and storage.

Use containers specifically designed for kerosene, such as blue galvanized steel safety cans, which are clean, dry, and tightly sealed to prevent contamination and evaporation.

Store kerosene in cool, well-ventilated areas away from ignition sources and water exposure, complying with OSHA and NFPA quantity limits. These storage areas should ideally be flammable liquids cabinets that meet all construction and ventilation requirements.

Always wear protective gloves and eye protection. Ensure ventilation during transfer, and use approved funnels or pumps to avoid spills.

Label containers clearly with hazard warnings and maintain segregation from incompatible materials. Equip storage zones with spill containment and fire extinguishers, and conduct regular inspections.

Following these protocols minimizes risks of fire, chemical reactions, and health hazards, guaranteeing safe kerosene handling and storage.

You shouldn’t mix kerosene with other fuels like gasoline or diesel unless you have expert guidance. Mixing can cause chemical incompatibilities, phase separation, or engine damage.

While small kerosene blends in diesel may aid cold performance, improper mixing risks clogging, incomplete combustion, and hazardous byproducts.

Always store kerosene separately in approved containers and consult equipment manufacturers before blending to guarantee safety and uphold fuel stability.

You should act quickly to contain kerosene spills by ventilating the area and isolating it.

Sprinkle absorbent materials like kitty litter or commercial pads over the spill.

Let them absorb for several minutes, then scrape off and dispose of the waste per hazardous regulations.

Avoid water and detergents to prevent spreading.

Wear protective gear. For large spills, contact professionals for specialized cleanup and proper hazardous disposal to minimize environmental impact.

Wondering if kerosene is safe for indoor heating? You can use it, but only with strict precautions.

Make certain the space is well-ventilated to avoid toxic emissions like carbon monoxide and nitrogen dioxide. Always use high-quality 1-K grade kerosene, never gasoline.

Refuel outdoors when the heater’s cool, and maintain clearance from flammables. Remember, prolonged use increases health risks, so limit usage and install carbon monoxide detectors for safety.

When you dispose of old kerosene improperly, you risk contaminating soil and groundwater, harming ecosystems and drinking water sources.

Kerosene’s chemicals persist, bioaccumulate, and disrupt biodiversity. Spills lead to long-term aquatic pollution and costly cleanup efforts.

You also expose yourself and wildlife to serious health hazards like respiratory issues and cancer risks.

Additionally, improper disposal violates regulations, triggering fines, legal action, and mandatory remediation. Handle kerosene waste responsibly to avoid these consequences.

You might be surprised, but kerosene is an excellent solvent and cleaning agent.

Its hydrocarbon makeup dissolves oils, greases, and stubborn residues effectively.

You can use it to degrease machinery, clean engines, or thin oil-based paints.

Its flash point also makes it safer than gasoline for handling.

When you need to remove tough dirt or prepare surfaces, kerosene’s solvent properties deliver reliable, industrial-strength cleaning performance.

You’ll find kerosene typically remains effective for one to five years, depending on storage conditions, container quality, and contamination levels. You must store it in airtight, approved containers, keep it cool and dry, and regularly check for cloudiness or sediment.

You shouldn’t use degraded kerosene, as it compromises engine performance and safety. By monitoring, protecting, and properly handling your kerosene, you’ll guarantee fuel reliability, maximize efficiency, and maintain safe operation.