Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

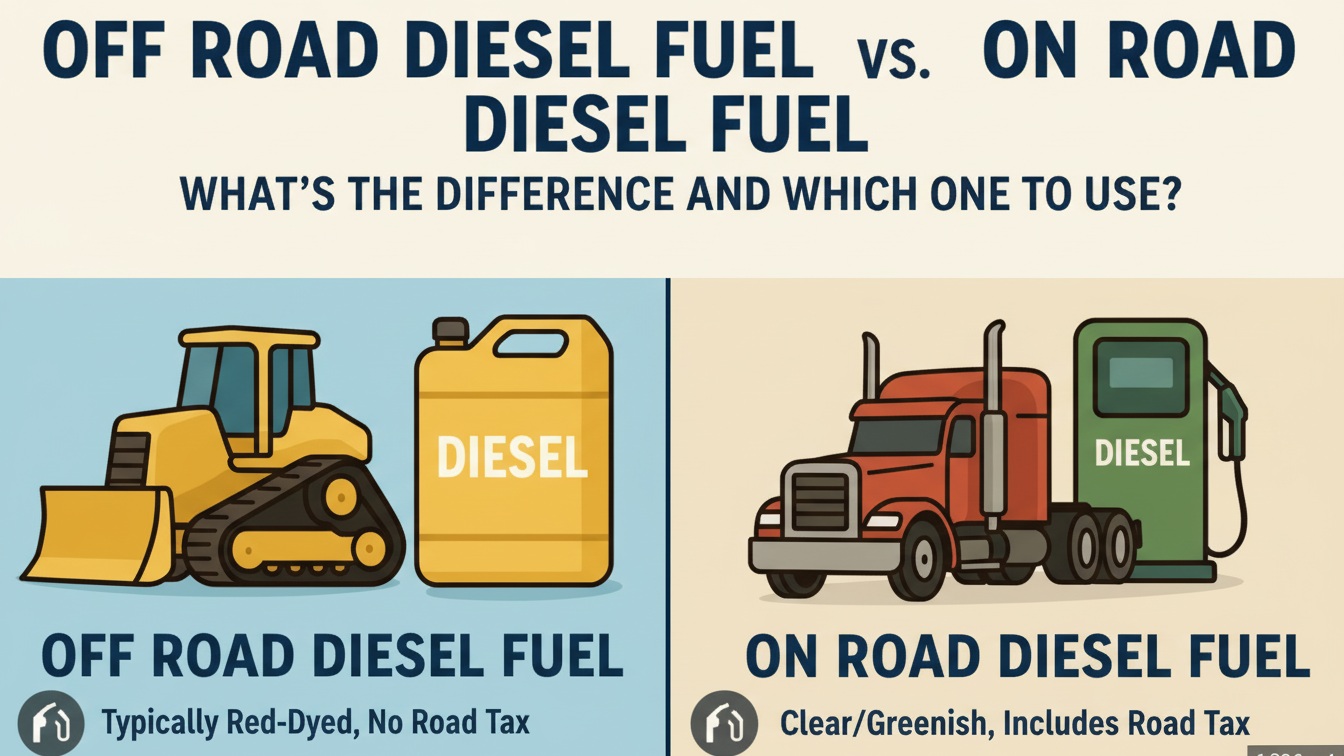

You’ll find off-road diesel and on-road diesel share nearly identical chemical makeup, both meeting ultra-low sulfur standards for engine efficiency. The key differences lie in taxation, authorized use, and dye identification.

Off-road diesel is dyed red and tax-exempt, meant for equipment off public roads. On-road diesel is clear or green-tinted for highway vehicles with full taxes. Using the wrong diesel risks legal penalties and engine damage.

Understanding these distinctions helps you optimize fuel use and compliance.

| Feature | Off-Road Diesel | On-Road Diesel |

|---|---|---|

| Dye Color | Red (Solvent Red 26) | Clear or green tint |

| Tax Status | Exempt (cheaper by 20-25¢/gallon) | Full federal/state taxes |

| Primary Uses | Farm equipment, construction | Highway trucks, cars |

| Sulfur Limit | 15 ppm ULSD | 15 ppm ULSD |

| Legal Risks | Fines up to $10,000 if misused | Fully compliant for roads |

| Engine Impact | Higher contamination risk | Optimal for emissions systems |

Although both on-road and off-road diesel fuels power diesel engines, they serve distinct purposes and comply with different regulations.

You’ll find on-road diesel designed for vehicles operating on public highways, including passenger cars, trucks, and buses. It meets strict emissions standards and is subject to federal and state excise taxes. It is also formulated to provide optimal engine protection for high-mileage use.

On-road diesel typically appears clear or light amber.

In contrast, off-road diesel fuels equipment used off public roads, like agricultural machinery, construction equipment, and mining vehicles. It’s dyed red to distinguish it and avoid misuse, and it’s exempt from highway fuel taxes. Also known as dyed diesel, it is designated for off-road use only to ensure compliance with specific regulations.

Using off-road diesel in on-road vehicles is illegal and can result in penalties. Each fuel type caters to its specific operational environment and regulatory requirements, ensuring proper performance and legal compliance.

Both on-road and off-road diesel fuels have a pretty similar base chemical structure, mainly made up of hydrocarbons. If you look closely, their approximate formula is C12H23. Pretty interesting, right? This similarity in base composition is somewhat analogous to the difference in base oils used in motor oils like Pennzoil and Quaker State, where the source impacts performance.

However, when it comes to regulations for sulfur content, there’s a key difference. On-road diesel is restricted to ultra-low sulfur levels, which means it can only have about 15 parts per million (ppm) to meet those stricter emissions standards.

Off-road diesel, on the other hand, used to have higher sulfur limits. But nowadays, in many regions, it also needs to comply with those ULSD limits. Quite a shift, don’t you think? European standards have significantly reduced sulfur content over the past 20 years.

And let’s not forget about biodiesel blends. They can vary between these two types of fuels, which can really impact both their chemical properties and how they comply with regulations. It’s a complex landscape, but an important one to understand! These blends influence factors like engine compatibility, similar to how motor oils are formulated for specific engine types.

When comparing off-road and on-road diesel fuels, you’ll find their base chemical compositions are fundamentally the same, primarily consisting of hydrocarbons with formulas around C12H23.

Both fuels contain about 75% saturated hydrocarbons, including paraffins and cycloparaffins, and 25% aromatic hydrocarbons, such as naphthalenes and alkylbenzenes. These compositions influence the fuels’ viscosity characteristics, which affect flow and combustion efficiency.

Regulatory standards like ASTM D975 define chemical and physical properties to maintain consistent cetane numbers, flash points, and distillation profiles across both fuel types.

While on-road diesel must meet stringent EPA Ultra-Low Sulfur Diesel requirements since 2006, off-road diesel achieved similar sulfur standards by 2014. State-level regulations can impose additional chemical constituent limits on off-road diesel.

Additives and dyes differentiate off-road diesel legally but don’t alter its fundamental chemical properties or combustion performance compared to on-road diesel. Both fuels are chemically identical, providing the same engine performance despite regulatory distinctions.

Since sulfur content directly impacts emissions and engine performance, regulatory agencies strictly limit sulfur levels in diesel fuels.

In the U.S., both on-road and off-road diesel fuels must comply with the Ultra-Low Sulfur Diesel (ULSD) standard, limiting sulfur to 15 ppm. This standard phased in for on-road diesel starting June 2006 and for off-road diesel by June 2010, replacing previous limits of up to 500 ppm.

Locomotive and marine diesels followed with the same 15 ppm cap by June 2012. These regulations enable advanced emissions control technologies and reduce environmental impact. The transition to ULSD has also increased fuel processing costs, leading to higher pump prices and significant industry investment.

Proper additive formulations complement ULSD requirements to ensure fuel stability and engine protection despite lower sulfur content. Compliance is enforced through rigorous fuel testing, inspections, and record-keeping, with penalties for violators.

Internationally, sulfur limits vary, with the EU requiring 10 ppm and specific limits for marine fuels in Emission Control Areas.

Regulatory limits on sulfur content set the groundwork for cleaner diesel fuels, but the chemical makeup of biodiesel blends introduces additional factors affecting fuel performance and compliance. Understanding the viscosity differences between fuel types is crucial for optimal engine performance.

Biodiesel primarily contains fatty acid methyl esters (FAME) with varying unsaturation based on feedstock, differing chemically from the saturated hydrocarbons in petroleum diesel. Biodiesel consists of mono alkyl esters derived from vegetable oils or animal fats through transesterification using methanol.

Blends designated as B5, B20, or B100 impact properties like cetane number, viscosity, and cold flow, influencing engine operation. Proper selection of blends according to climate and engine specifications helps reduce wear and maintain efficiency.

You must consider ASTM standards (PS 121 for biodiesel, D975 for blends) that enforce criteria on cetane, viscosity, and contaminants such as glycerol. Additives like methanol modify flash point and density but remain regulated.

Following OEM blend limits ensures compatibility, while strict quality controls prevent engine damage and maintain emission compliance across both on-road and off-road applications.

Did you know that you can easily spot off-road diesel just by looking at its color? It has this distinctive red dye, which is a clear indicator that it’s untaxed and meant for non-highway use. On the other hand, on-road diesel usually looks clear or has a slight green tint. This color difference shows that it’s tax-paid.

Understanding these dyes is pretty important! While they don’t affect how your engine performs, they do help ensure that you’re following regulations. The red dye, made from Solvent Red 26 and 164, is used specifically for regulatory compliance to distinguish off-road diesel from on-road fuel.

The answer lies in the addition of red dye, specifically Solvent Red 26, mandated by the EPA and IRS. This dye visually marks off-road diesel, enabling regulators to identify untaxed fuel use in on-road vehicles quickly.

You’ll find this dye highly concentrated and stable, ensuring persistence in fuel tanks and engine parts for reliable detection. Tax officials employ visual inspections, dip tests, and black light scans to detect even trace dye residues, deterring illegal usage.

Red-dyed diesel is legally restricted to off-road applications like agriculture and construction, with strict penalties for misuse. This purposeful coloration supports regulatory enforcement, tax compliance, and prevents fuel tax evasion effectively.

Primarily used in off-road machinery such as tractors and bulldozers, red diesel serves industries like farming and construction, ensuring it is not used unlawfully on public roads.

Although not mandated by federal law, on-road diesel fuel in the United States typically exhibits a clear or slightly green tint, which helps in visual identification and quality control.

Refineries or terminal providers add a green dye that imparts this hue, allowing you to quickly distinguish on-road diesel from off-road variants. This practice is similar to how different automotive fluids use color coding to aid identification and prevent misuse.

Fresh on-road diesel appears bright with a subtle green shade, but the tint fades over time, turning yellow or darker as the fuel ages. This visual cue assists inspectors in verifying fuel compliance without advanced testing.

Unlike off-road diesel, which contains federally mandated red dye, on-road diesel’s green coloration is optional but commonly employed to maintain quality standards and facilitate straightforward visual checks during fueling or roadside inspections.

In contrast, off-road diesel is dyed with Solvent Red 26 as part of regulatory measures to prevent fuel laundering and theft.

Since diesel fuel dyes serve primarily for identification and regulatory purposes, they don’t negatively affect engine performance or longevity.

The dyes, such as Solvent Red 164, are added at controlled concentrations to enable quick visual differentiation. Red dye indicates off-road diesel exempt from road taxes.

This visual marker aids in compliance inspections without altering combustion or fuel properties. While off-road diesel historically contained higher sulfur levels, modern ultra-low sulfur formulations minimize engine impact. Moreover, dyed diesel is considered environmentally friendly by lowering water contamination risks.

Be aware that improper dye formulations could clog fuel systems, but regulated dyes prevent this. Using dyed off-road diesel in on-road vehicles is illegal and triggers regulatory penalties, not mechanical damage. The additives in diesel formulations also help maintain oxidation stability to protect engine components.

Therefore, the dye’s role is strictly compliance-focused, ensuring you can easily distinguish fuel types without compromising engine integrity.

When you compare off-road and on-road diesel fuels, sulfur content plays a crucial role in their environmental impact.

Since 2006, US on-road diesel has been capped at 15 ppm sulfur, with off-road diesel following by 2010 after a phased reduction from higher limits. Monitoring and enforcement ensure these sulfur reductions are maintained to support emission control technologies.

High sulfur levels increase sulfur dioxide emissions, causing acid rain, smog, and respiratory issues.

Elevated sulfur in diesel fuels leads to harmful sulfur dioxide emissions, contributing to acid rain, smog, and health problems.

Ultra-low sulfur diesel (ULSD) reduces particulate matter emissions by over 90%, enabling advanced emission controls. The use of ULSD also helps improve engine performance and fuel efficiency, leading to lower maintenance costs.

Canada and the EU enforce similar stringent limits of 15 ppm and 10 ppm sulfur, respectively, reflecting a global trend toward lower sulfur content.

Compliance is monitored rigorously through testing and enforcement, ensuring fuel meets standards to minimize environmental harm and improve air quality.

Because on-road and off-road diesel fuels both meet Ultra-Low Sulfur Diesel (ULSD) standards, you can use either fuel in modern diesel engines without immediate compatibility issues.

Both fuels share similar cetane ratings and energy densities, ensuring consistent ignition, combustion, and power output. Your engine’s fuel system, including injectors, pumps, and filters, handles both types without modification or performance loss, demonstrating the importance of engine compatibility.

While older diesel engines are less sensitive to fuel variations, modern engines with emissions controls tolerate off-road diesel temporarily without mechanical or emissions system failure. However, note that mixing fuels with different sulfur contents can potentially clog or damage emission control components over time.

Switching between fuels requires no engine recalibration or downtime. Cold-weather performance depends more on additives and storage than fuel classification.

Using off-road diesel in your engine introduces specific maintenance challenges not typically encountered with on-road diesel.

Off-road diesel’s higher risk of dirt, water, and microbial contamination demands frequent inspection and replacement of fuel and air filters to prevent clogging and injector damage. Selecting the proper fluid type and specifications is critical to maintaining optimal engine performance.

Off-road diesel’s contamination risks require frequent fuel and air filter checks to avoid clogging and injector damage.

Water presence accelerates corrosion in fuel lines, necessitating water separators and pre-filters.

Lower fuel quality can cause incomplete combustion, resulting in soot buildup and increased engine deposits, which require more frequent injector cleaning. You’ll also need shorter oil change intervals, as lubricating oil degrades faster under harsh off-road conditions.

Regular cleaning of the engine exterior and undercarriage is essential to remove abrasive materials that can interfere with engine components and reduce performance. This includes using a high-pressure hose to eliminate mud, dust, and debris.

Without diligent maintenance, soot accumulation, corrosion, and filter clogging markedly shorten engine longevity.

Adhering to rigorous filtration and cleaning schedules guarantees ideal combustion, protects fuel systems, and extends engine life when using off-road diesel. Additionally, using synthetic fluids in maintenance can enhance durability and reduce wear under severe operating conditions.

Although off-road and on-road diesel fuels serve similar purposes, their pricing structures differ markedly due to distinct taxation policies. You’ll find that on-road diesel incurs a federal excise tax of $0.244 per gallon plus an average state tax around $0.4024 per gallon, substantially increasing its cost.

Off-road diesel, dyed red to denote tax-exempt status, avoids these federal and most state excise taxes, facing only a minimal $0.001 per gallon LUST fee. This exemption applies strictly to non-highway uses like agriculture and construction.

Because tax collection occurs at terminals or bulk points, compliance requires accurate reporting and certification. Fuel sold to government entities for exclusive use is also exempt from federal excise taxes when proper certification is provided.

These taxation differences make off-road diesel typically 20–25 cents cheaper per gallon, reflecting tax burdens rather than fuel quality. This directly impacts your fuel procurement strategy.

When you operate an on-road vehicle with off-road diesel, you risk significant engine damage and legal consequences. Off-road diesel’s higher sulfur content and lack of additives cause engine wear, clogged filters, and reduced performance.

Additionally, off-road diesel is taxed less because it is intended for use in non-public road machinery, which highlights the importance of using the correct fuel for your vehicle.

Authorities detect misuse via red dye inspections, imposing fines up to $10,000, vehicle impoundment, or prosecution. Misuse also breaches environmental regulations, risking sanctions.

| Risk Type | Consequence | Impact |

|---|---|---|

| Engine Damage | Clogged filters, wear | Costly repairs |

| Legal Penalties | Fines, prosecution | Financial loss |

| Environmental | Increased emissions | Regulatory sanctions |

| Business | Reputation damage | Operational disruption |

Prevent these risks by strictly using the correct diesel type to guarantee compliance, engine longevity, and legal safety.

Since off-road diesel is formulated for heavy-duty, non-highway equipment, it plays a critical role in agriculture, construction, and industrial sectors.

You’ll find it powering tractors, harvesters, excavators, forklifts, and large generators, all designed to handle its higher sulfur content and lower refinement.

In agriculture, off-road diesel fuels about 75% of machinery, enabling efficient planting and harvesting while reducing fuel costs due to tax exemptions.

Construction sites depend on it for continuous operation of heavy machinery and stationary generators essential for infrastructure projects. Off-road diesel is typically dyed red to prevent its misuse on public roads.

Industrial facilities utilize off-road diesel to maintain uninterrupted production in manufacturing and mining environments where emissions regulations are less stringent.

Its chemical properties and cost-effectiveness make off-road diesel indispensable for these demanding, specialized applications.

Yes, you can blend off-road diesel with biodiesel at home, but you must measure accurately to maintain proper ratios, typically up to B20.

Confirm both fuels meet ASTM standards to avoid engine issues. Keep in mind, higher blends risk filter clogging and cold-flow problems.

Check your engine’s OEM recommendations for optimal performance, and store fuels properly to prevent degradation. Always handle blending with care, considering legal and tax regulations.

You add red dye to off-road diesel during refining or blending by injecting liquid Solvent Red 26 or 164 into large fuel volumes with precision metering systems. Mixing tanks guarantee uniform dye distribution, preventing uneven coloration.

Strict quality control verifies concentration meets regulatory standards, maintaining the dye’s stability throughout storage and transport. This process ensures clear identification and compliance with tax and environmental regulations.

Yes, seasonal additives are used differently in on-road versus off-road diesel. You’ll find on-road diesel typically includes cold-flow improvers and cetane boosters blended at refineries to meet strict regulations.

Off-road diesel often uses higher additive concentrations, including kerosene blends and biocides, to handle storage and extreme cold.

Since off-road diesel isn’t taxed the same, you might apply additives on-site, giving you more flexibility but impacting cost and performance differently.

Picture a fortress guarding a volatile treasure. That’s how you should treat off-road diesel storage.

Use approved, corrosion-resistant tanks with airtight seals and flame arrestors.

Position them away from ignition sources and high traffic, in cool, ventilated areas.

Implement leak detection, spill kits, and maintain strict no-smoking zones.

Secure the site with locks and surveillance, and make certain only trained personnel handle fuel wearing proper PPE.

Regular inspections and documented safety drills keep risks controlled.

You’ll notice on-road diesel delivery happens at retail stations with standardized pumps for quick, individual refueling.

This supports spontaneous needs. In contrast, off-road diesel is delivered in bulk directly to onsite storage tanks at fixed locations like farms or construction sites, often scheduled in advance.

This bulk delivery minimizes downtime and suits large fuel demands, while on-road systems focus on convenience, accessibility, and compliance with taxation and quality regulations.

When it comes to off-road and on-road diesel fuel, remember: “You get what you pay for.” Using the right diesel guarantees ideal engine performance, compliance with regulations, and avoids costly legal issues.

Off-road diesel, dyed and taxed differently, suits heavy machinery but not highway vehicles. On-road diesel meets stricter standards for emissions and engine longevity.

Choosing properly keeps your equipment running efficiently and protects you from fines and maintenance headaches.