Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

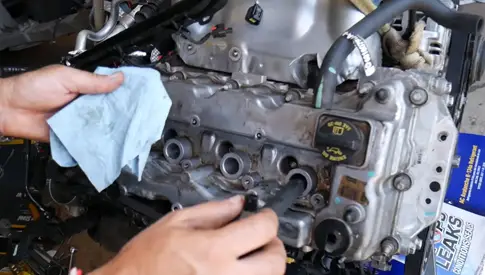

Regular vehicle maintenance is a must, and a part of this includes changing the engine oil. However, there may be instances when the oil plug is over-tightened, making it difficult to remove. This can lead to damaging the engine. However, there are several methods to remove an over-tightened oil plug safely and efficiently.

You can use lubricants or rust remover to help remove an over-tightened oil plug. Also, the correct tools, such as a hex key or socket wrench, can aid in the removal process. A Gator Grip pipe wrench or bolt extractor may be necessary as a last resort to loosen and remove the oil plug.

Today, we will discuss some of the best techniques to help you do the job smoothly. So keep reading for detailed information.

To remove an over-tightened oil plug, you can try several methods.

You can start by applying a lubricant or rust remover to the stuck oil plug. This will help to loosen the threads and make it easier to remove the plug. An appropriate product to use is WD-40 or any other oil or rust remover designed for this purpose.

Apply a generous amount of the lubricant to the plug and let it sit for a few minutes to allow penetration. Once the lubricant has had a chance to work, try turning the plug left six times and then right once. This back-and-forth motion will help to loosen the plug further.

If the plug remains stubborn, gently tap it with a medium-sized hammer. Be cautious not to apply too much force or damage the surrounding area.

You can also use a hex key to remove the over-tightened oil plug. Make sure the engine is cold before attempting this method.

Wet the area around the stuck plug with a lubricant or rust remover. This will help loosen any corrosion or debris that may be causing the plug to be stuck. Now insert the hex key into the plug and firmly grip the handle.

Slowly turn the key counterclockwise, using steady and controlled force. Be careful not to strip the plug or damage the surrounding area. If the plug doesn’t loosen after a few attempts, it may be necessary to seek professional assistance to avoid causing further damage.

To utilize a socket wrench for removing an over-tightened oil plug, follow these steps:

The Gator Grip pipe wrench is a valuable tool for tackling the challenge of an over-tightened oil plug. Its unique design allows it to grab hold of the stripped plug, providing the necessary grip to loosen it.

To use the Gator Grip pipe wrench, first select the appropriate size of the wrench that matches the plug. Ensure a snug fit to maximize grip.

Then, position the wrench around the plug and turn it counterclockwise to loosen it. The Gator Grip pipe wrench’s strong and durable construction allows for effective force application, facilitating the removal of even the most stubborn over-tightened oil plugs.

If the previous methods fail to loosen the over-tightened oil plug, it’s time to consider using a bolt extractor as a last resort. A bolt extractor is a specialized tool designed to grip onto a rounded or damaged bolt or screw head and provide the necessary torque to remove it.

You’ll need to select the appropriate size extractor for your oil plug to use a bolt extractor. Insert the extractor into the oil plug and ensure it’s securely seated. Use a wrench or ratchet to turn the extractor counterclockwise. The extractor’s reverse spiral design will bite into the oil plug, allowing you to apply the necessary force to remove it.

There are several causes for an over-tightened oil plug.

Sludge is a thick, gel-like substance that can form when the engine oil change is overdue. Over time, this sludge accumulates in the oil pan, creating a sticky and stubborn residue.

When attempting to remove the oil plug, the presence of sludge can make it difficult to loosen. Mechanics may overtighten the plug to prevent leaks caused by the sludge.

The excessive tightening can result in a stuck or stripped oil plug, making it even more challenging to remove and potentially leading to damage to the oil pan or plug threads.

Overzealous tightening during maintenance can lead to several causes of an over-tightened oil plug. One common cause is using the wrong size wrench or socket, which can result in applying more force than necessary.

Another cause is using a torque wrench set to a higher value than recommended by the vehicle manufacturer. Also, using a damaged or worn-out oil plug gasket can lead to over-tightening in an attempt to prevent leaks.

Finally, lack of proper lubrication on the oil plug threads can cause resistance during tightening, leading to excessive force being applied.

Rust can develop when moisture and environmental factors come into contact with the metal surfaces. Over time, this rust can create a tight bond between the plug and the oil pan, effectively welding them together.

The presence of rust makes it extremely difficult to remove the plug without using lubricants or specialized tools. The rust acts as a barrier, increasing the friction between the plug and the oil pan, making it harder to loosen the plug.

When tightening an oil plug, be aware that different materials can react differently, leading to an over-tightened plug. Oil pans and plugs are commonly made of materials such as steel or aluminum. These materials have distinct properties that affect their response to temperature changes.

Steel tends to expand and contract at a slower rate compared to aluminum. As a result, if an oil plug made of steel is tightened when the engine is hot, it may become excessively tight as the steel cools and contracts.

However, an oil plug made of aluminum may not experience the same level of contraction, leading to a looser fit. Understanding the material composition of the oil plug and oil pan is crucial in preventing over-tightening or under-tightening, ensuring proper sealing, and avoiding potential damage to the oil pan threads.

One common mistake is using the wrong tools during the oil change process. Using a wrench that’s too long or short can result in excessive force being applied to the plug, causing it to be over-tightened.

Also, not applying the correct amount of torque can lead to over-tightening. Following the manufacturer’s specifications and using a torque wrench to ensure the plug is tightened to the recommended level is crucial.

Another error that can cause an over-tightened oil plug is cross-threading. This occurs when the plug isn’t aligned properly with the threads, resulting in a tight fit that’s difficult to remove. Aligning the plug correctly and applying steady pressure while tightening can help prevent this issue.

When an oil plug is over-tightened, several consequences can occur.

Over-tightening an oil plug can significantly damage the plug itself, resulting in potential leaks or stripped threads. When an oil plug is tightened beyond its recommended torque specification, it can cause the plug to distort or crack. This can compromise the integrity of the plug, allowing oil to leak out.

Additionally, the excessive force applied while tightening can strip the threads of the plug or the corresponding threads in the oil pan. This can make it difficult to secure the plug in the future properly, leading to further leaks and potential engine damage.

If you over-tighten the oil plug, you risk damaging the threads in the oil pan. The consequences of such damage can be significant and may require expensive repairs.

When the threads in the oil pan are damaged, it can result in oil leaks. This can lead to a loss of lubrication for the engine, causing increased friction and heat. Over time, this can lead to engine damage and potentially catastrophic failures.

Furthermore, if the threads are severely damaged, it may become impossible to secure the oil plug properly. This can result in the plug coming loose during operation, leading to a sudden loss of oil and potentially causing severe engine damage.

The rubber gasket, also known as the oil plug washer or oil drain plug gasket, is crucial in sealing the connection between the oil pan and the oil plug.

When the oil plug is over-tightened, it exerts excessive pressure on the rubber gasket, causing it to deform or tear. This can lead to oil leakage, which isn’t only messy and dangerous for your engine.

The consequences of a compromised rubber gasket include oil seepage, loss of lubrication, and potential engine damage.

When tightening an oil plug, be mindful of the risk of engine damage or catastrophic failure from over-tightening. Over-tightening the oil plug can lead to severe consequences for the engine.

One of the primary risks is the stripping or cracking of the oil pan threads. This can result in oil leaks, leading to lubrication loss and increased engine friction. Without proper lubrication, the engine components can wear out faster, causing significant damage and reducing lifespan.

Additionally, over-tightening the oil plug can cause the gasket to deform or rupture, leading to oil leaks and potential engine overheating. The excessive force applied during over-tightening can also damage the oil plug, making removing it challenging and requiring more expensive repairs.

You can use a torque wrench to remove the oil drain plug easily. A torque wrench is a precision tool that allows you to apply a specific amount of force to a fastener.

To loosen an over-tightened oil drain plug, set your torque wrench to the appropriate value specified by the manufacturer. Make sure to use the correct size socket or wrench attachment that fits securely onto the drain plug.

Attach the torque wrench to the drain plug and turn it counterclockwise until it loosens. If you encounter resistance, don’t apply excessive force, which may damage the drain plug or the surrounding components. Instead, use a breaker bar or a longer handle for additional leverage.

In certain situations, drilling out the oil drain plug can be a viable option to remove it. However, it should only be considered a last resort when all other methods fail. Drilling should be approached with caution, as it carries the risk of damaging the oil pan.

You’ll need to center the drill bit on the plug and create a pilot hole to drill out the plug. Once the pilot hole is drilled, a screw extractor can remove the plug by gripping it onto the newly created hole.

Removing an over-tightened oil plug requires some careful steps. The above methods can help you safely and efficiently remove a stubborn oil plug. It’s important to take caution, as damaging the engine or oil pan can lead to more costly repairs.

If you’re not confident about working with engines, seek professional assistance. Keep in mind that regular maintenance ensures your vehicle runs smoothly day in and day out.

Just like untangling a stubborn knot, freeing the oil plug requires patience and careful handling to ensure a smooth and successful removal process.