Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

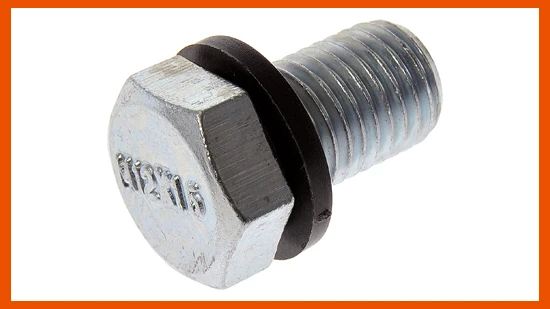

The tightness of your oil drain plug after an oil change might just seem like a small detail, but it keeps your engine running smoothly for longer.

Too loose, and you risk oil leaks and potential engine damage. Too tight, and you risk stripping the threads in your oil pan or damaging the plug itself. So, how tight should your oil drain plug be to prevent oil leaks and avoid damaging the gasket?

After researching, I found the recommended torque specification, which is between 20-30 foot-pounds of torque. This is described as “hand-tight, plus a little more.” To achieve this, hand-tighten the plug until it is flush with the oil pan. Then, use a torque wrench to add that extra 1/4 turn to snug it up.

I’ll explain how to tighten the oil drain plug after an oil change and what over-tightening can do.

To properly tighten the oil drain plug after an oil change, follow these two key steps.

Step 1: Hand-tighten the plug

Step 2: Use a wrench to snug it up

After draining the old oil, insert the oil drain plug into the drain hole by hand, ensuring that it’s gently threaded into place and not cross-threaded. Use a firm grip to turn the plug clockwise until it’s flush with the oil pan.

Now, to ensure a proper oil drain plug tightening after an oil change, use an appropriate wrench or socket size to snugly turn the plug until it stops.

To complete the installation, you will need to turn the wrench an additional 1/4 turn. This extra turn ensures that the plug is firmly in place and prevents it from loosening during normal operation.

These steps remain the same regardless of the oil drain plug size, material, or type, making it a universally applicable approach for securing your engine’s oil system.

Over-tightening the oil drain plug can have several consequences, such as:

When you overtighten the oil drain plug, it can cause stripped threads in the oil pan, which could lead to costly repairs. The oil pan is typically made of softer materials than the drain plug, such as aluminum or steel.

When excessive force is applied during installation, the threads in the oil pan can become damaged or worn down. Therefore, it’s crucial to exercise caution and adhere to the recommended torque specifications when tightening the oil drain plug to avoid stripping the threads.

If you tighten the oil drain plug too much, it can cause leaks due to excessive pressure on the gasket or washer. When the drain plug is over-tightened, the gasket or washer can become deformed, leading to an imperfect seal. This imperfection allows oil to seep out over time, creating a leak.

Additionally, over-tightening can damage the threads on the oil pan, making it difficult to achieve a proper seal even with a new gasket or washer. The consequences of these leaks can be significant. Oil loss can occur, potentially leading to engine damage if the oil level drops too low.

Over-tightening the plug on your oil pan can cause major problems during your next oil change. Specifically, it can make the removal of the bolt extremely challenging and lead to the rounding or damaging of its head.

These issues can then require more complex and costly repairs to fix. Therefore, it is crucial to adhere to the recommended torque specification and avoid excessively tightening the plug. Doing so will save you from potential headaches and expenses down the road.

Over-tightening the oil drain plug can lead to a cracked oil pan, causing catastrophic oil loss and potential engine damage. When the plug is tightened beyond the recommended torque specification, it exerts excessive pressure on the oil pan, which can result in cracks forming.

A cracked oil pan can lead to oil leakage, compromising the lubrication of crucial engine components. This can cause increased friction, overheating, and accelerated wear and tear on the engine.

Furthermore, the loss of oil can result in insufficient lubrication, leading to metal-to-metal contact and further damage. In addition to the costly repair of replacing the oil pan, the engine may require extensive repairs, including possible replacement.

An oil drain plug can potentially come loose automatically, leading to significant problems. Factors like vibration, temperature changes, and engine oil pressure fluctuations can cause the plug to loosen slowly over time.

Regularly checking for oil leaks and ensuring the plug is securely in place during routine maintenance is essential. If you experience an unexpectedly loose oil drain plug, address it promptly to prevent oil leaks, engine damage, or other complications.

It’s generally not advisable to use Teflon tape on your car’s oil drain plug before tightening it. Teflon tape, also known as PTFE tape, is commonly used for sealing threads in plumbing applications but isn’t suitable for the high temperatures and pressures found in an engine’s oil system.

It may not provide a secure and reliable seal for your oil drain plug, which can lead to oil leaks and potential complications.

It is now clear that properly tightening the oil drain plug after an oil change is crucial for the longevity and health of your vehicle’s engine. Follow the recommended torque specifications that I share, typically between 20-30 foot pounds of torque or a little more than hand-tight.

You can ensure a secure fit by adhering to these guidelines without the risk of damage or complications. Over-tightening the oil drain plug can lead to issues like stripped threads, leaks, and even a cracked oil pan, all of which can result in costly repairs.

The right tightness and proper installation techniques are key to keeping your engine running smoothly and avoiding future headaches.