Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Yes, diesel fuel does stain concrete by quickly penetrating its porous surface and leaving behind persistent oily marks. Its low surface tension and chemical makeup allow it to bond deeply, making stains tough to remove with water alone.

Over time, diesel can also weaken the concrete structure. You can tackle stains using absorbents and degreasers, or protect surfaces with sealers. If you want to understand the chemistry behind these stains and practical removal and prevention tips, keep exploring the details.

Although concrete is a durable material, diesel fuel interacts with its surfaces in ways that can compromise both appearance and structural integrity. Diesel, a non-polar hydrocarbon, penetrates porous concrete, causing persistent oily stains that resist water-based cleaning.

Oils with advanced additive technology, such as synthetic motor oils, demonstrate superior performance in protecting surfaces, which contrasts with diesel’s degrading effects on concrete. The porosity and surface texture of concrete directly affect how deeply diesel is absorbed and how severe staining becomes.

Beyond aesthetics, diesel contamination alters surface properties, potentially roughening or softening the cementitious matrix. This degradation can extend drying times and evaporation rates due to diesel’s low volatility.

Repeated or prolonged exposure risks microstructural damage, weakening concrete over time. Additionally, diesel particulate matter deposits on surfaces, causing discoloration and mineralogical changes, though chemical penetration remains limited by concrete’s alkalinity.

Laboratory studies show that such exposure can lead to rapid particulate matter deposition on concrete surfaces even within short periods, accelerating material decay. Understanding these interactions is vital for managing diesel’s impact on concrete durability and appearance.

When you examine diesel fuel’s chemical properties, you see why it causes persistent stains on concrete. Diesel’s composition includes paraffins, naphthenes, and aromatic hydrocarbons like naphthalenes and alkylbenzenes, which strongly adhere to surfaces.

Its chemical structure influences properties like freezing point, vaporization temperature, and safety, which also affect how it interacts with various materials including concrete. The use of advanced additive technology in fuels and oils can alter how these substances interact with surfaces.

Its average formula, C12H23, reflects a high carbon content—about 86% by weight—contributing to its oily nature. Diesel’s lower surface tension and viscosity enable it to penetrate porous concrete easily.

The aromatic compounds chemically bind to the substrate, intensifying stains. Additionally, diesel’s limited water solubility hinders easy removal once absorbed.

Its boiling range (170–360°C) and flash point (52–96°C) mean it evaporates slowly, allowing stains to set. These chemical traits collectively cause diesel to leave deep, stubborn stains on concrete that resist standard cleaning methods. The presence of paraffins and cycloparaffins in diesel also contributes to its tenacious adherence to surfaces, making removal more difficult.

Because diesel fuel penetrates concrete’s porous structure and interacts chemically with its components, it considerably undermines the material’s durability. Diesel contamination weakens the internal matrix, reducing compressive strength and elasticity, which compromises load-bearing capacity and resilience.

However, common oils such as diesel are typically non-detrimental to mature concrete in terms of long-term structural damage. Additionally, the base oil composition of diesel-related substances can influence the extent of their interaction with concrete.

In fresh concrete, diesel coats cement and fine aggregates, hindering hydration and bonding. This interference can lead to up to 25% strength loss. Even hardened concrete can experience mild long-term damage due to diesel’s penetration and chemical interference.

Continuous exposure promotes microstructural degradation through pore clogging and hydrocarbon contamination. This process increases porosity and brittleness, accelerating deterioration such as freeze-thaw damage.

As a result, maintenance needs rise significantly. Overall, diesel contamination diminishes concrete’s mechanical properties, shortens its lifespan, and raises repair costs.

If you want to effectively remove diesel stains from concrete, you need to combine chemical, mechanical, and absorbent methods tailored to the stain’s age and severity.

Start by applying an absorbent like cat litter or baking soda on fresh spills to soak up diesel. This helps prevent the stain from setting in. It is also important to protect surrounding areas to prevent damage during cleaning. Using protective gear and ensuring proper ventilation during cleaning can also minimize exposure to harmful fumes.

For set-in stains, use a concrete degreaser and allow it to dwell on the surface before scrubbing with a stiff brush. This breaks down the diesel residue effectively. Rinse with hot water to enhance the detergent’s action. Repeated cycles of degreasing and scrubbing may be necessary for stubborn stains.

Pressure washing can assist in removing residues but should be used cautiously to avoid damaging the concrete surface.

| Method Type | Recommended Products | Application Tips |

|---|---|---|

| Absorbent | Cat litter, baking soda | Apply immediately, sweep away |

| Chemical | Concrete degreasers | Allow dwell time before scrubbing |

| Mechanical | Wire brush, pressure washer | Use moderate pressure for scrubbing |

Although diesel spills can quickly stain concrete, you can considerably reduce this risk by implementing targeted prevention strategies. Start by applying concrete sealers or epoxy coatings to create impermeable barriers, especially in high-traffic zones.

Filters with reinforced construction demonstrate enhanced durability in harsh environments, a principle that can inspire protective surface treatments. Use mats or drip trays beneath vehicles to capture spills before they contact surfaces.

Design fueling areas with containment curbs and proper drainage to direct runoff away from concrete. Train personnel on proper fueling techniques, using funnel tools and spill-proof containers to minimize leaks. Maintain regular inspections and renew protective coatings as needed.

Respond promptly to spills by blotting with absorbents like sawdust—avoid scrubbing to prevent deeper penetration. Employ specialty cleaners formulated to inhibit staining, and dispose of contaminated materials per hazardous waste protocols. Regular use of OTIS Multi-Surface Cleaner helps pre-treat stains and prevent buildup.

Yes, you can remove diesel fuel stains using household products like dish soap, powdered laundry detergent, and WD-40. Apply these with stiff brushes and hot water for better results. You’ll need to scrub repeatedly and be patient, especially with older stains.

Absorbents like cat litter help with fresh spills. However, some deep-set stains might resist complete removal, requiring professional cleaners or specialized degreasers for thorough cleaning.

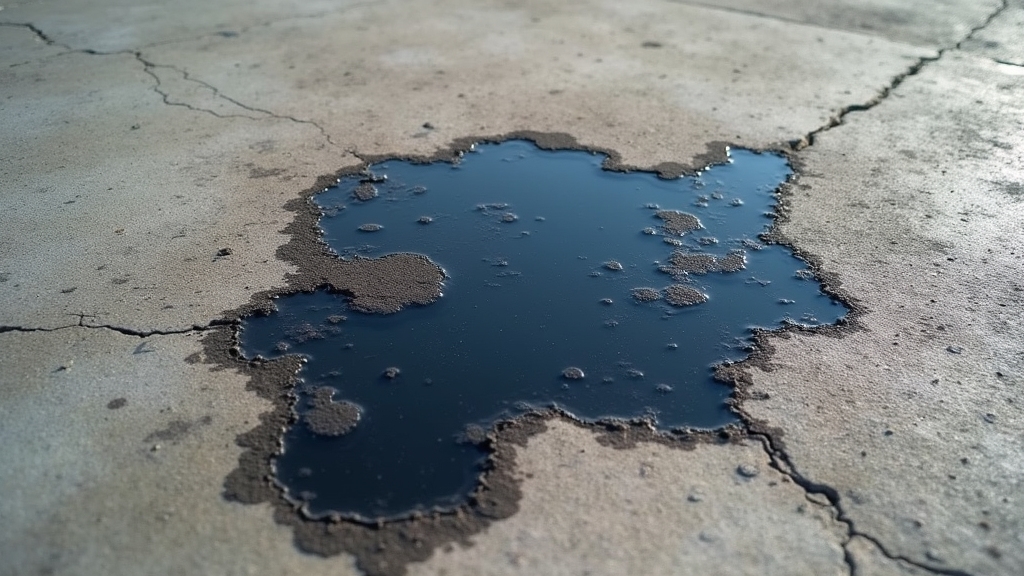

Imagine dark diesel seeping like ink into the tiny pores of concrete, the stain starts setting almost immediately after contact. Within hours, the fuel penetrates deeply, making removal harder as time passes.

If left untreated for days or weeks, the stain firmly embeds, resisting cleaning efforts. Acting quickly within hours to a day lets you prevent permanent setting by washing away surface diesel before it sinks into the concrete’s texture.

Yes, diesel stains on concrete harm the environment. When diesel seeps into porous concrete, it contaminates underlying soil and groundwater, disrupting ecosystems and threatening drinking water quality.

You should know diesel hydrocarbons are toxic to soil microbes, plants, and aquatic life, causing long-term damage. Plus, diesel vapors degrade air quality, posing respiratory risks. Prompt cleanup and remediation are essential to minimize these environmental hazards effectively.

Oh, sure, just crank up the heat and watch those diesel stains magically disappear—if only!

In reality, temperature doesn’t change whether diesel stains concrete but does influence how fast it soaks in. Higher temperatures speed up diesel’s penetration and can make stains look worse initially.

You’ll also find stain removal varies with temperature, as warmer conditions alter diesel’s viscosity and evaporation, impacting how effectively you can clean the concrete.

Yes, you can often reverse diesel fuel stains with professional cleaning services. Experts use industrial-grade degreasers, pressure washing, and bioremediation to break down and remove fuel residues.

However, success depends on stain age, concrete porosity, and cleaning method. Older, deep-set stains may require multiple treatments, and complete removal isn’t always guaranteed. Prompt professional intervention improves your chances of restoring the concrete’s appearance effectively and safely.

So, you’ve spilled diesel on concrete congratulations, you’ve just gifted your driveway a stubborn, oily tattoo. Diesel’s chemical makeup loves to seep in, compromising durability and aesthetics alike.

But don’t just stand there admiring the stain; act. Use effective cleaning methods promptly, or prepare for a permanent reminder of your fuel fiasco. And next time, try prevention because nobody wants a concrete canvas for their automotive accidents.